In the mining industry, conveyor belts play a fundamental role in the process of extracting and transporting minerals. These belts are responsible for moving large volumes of material over considerable distances. However, over time, these conveyor belts can accumulate dust, dirt and mineral residues, which can affect their efficiency and performance.

In this article, we will explain the need for regular cleaning of conveyor belts in the mining industry and, of course, the benefits!

Maintain operational efficiency.

Did you know that the accumulation of dust and dirt on conveyor belts can affect their ability to travel smoothly and steadily? This can result in delays and loss of productivity in the ore conveying process. Hence the importance of cleaning conveyor belts regularly, thus removing accumulated dirt and restoring their operational efficiency.

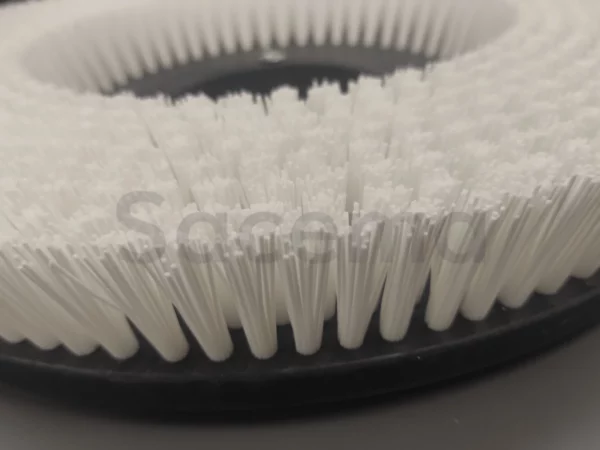

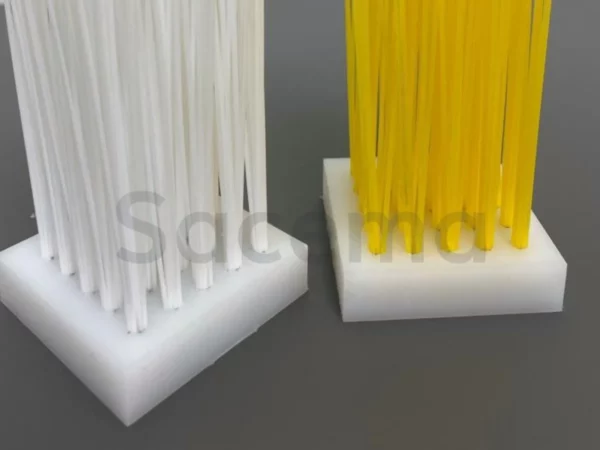

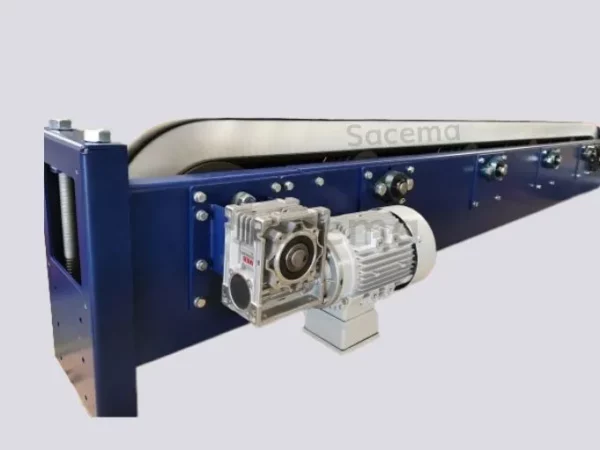

For this reason, at Sacema, we have the Conveyor Belt Cleaner, which consists of a motorized cylindrical industrial brush that rotates in the opposite direction to the belt advance, thus allowing a constant flow of the belt, without obstructions of material, which improves productivity and reduces downtime.

Prevention of cross contamination.

In the mining industry, it is common for conveyor belts to be used for different types of minerals. But… What happens if they are not cleaned properly? Particles from one mineral can be transferred to others, resulting in unwanted cross-contamination. This can affect the quality of the minerals transported and compromise production standards.

In summary, regular cleaning of conveyor belts will prevent cross-contamination while ensuring the integrity of the different materials.

Health and safety maintenance.

The accumulation of dust and mineral residues on conveyor belts can create a hazardous working environment. Airborne dust can affect air quality and workers’ health, especially if it contains toxic substances or fine particles that can be inhaled. In addition, dirt on belts can make surfaces slippery, increasing the risk of accidents and injuries.

If we are looking to maintain a safe working environment, regular cleaning… is indispensable!

Prolongation of the service life of the belts.

Of course, conveyor belts are an important investment in the mining industry, so it is crucial to maximize their service life. Accumulation of dirt and debris on belts can accelerate wear and reduce belt life. By regularly cleaning and removing unwanted materials, wear is minimized and the life of conveyor belts is extended, saving replacement and maintenance costs in the long run.

In short, regular cleaning of conveyor belts is essential in the mining industry to maintain operational efficiency, prevent cross-contamination, ensure the health and safety of workers, and prolong the life of the belts. For this task our Conveyor Belt Cleaner is ideal! A highly customizable product: the brush filaments, the type of anchorage, the motor power…. Moreover, it is a compact and relatively simple equipment, which makes it very economical.

So always remember to implement proper cleaning programs and use the necessary equipment and products to effectively remove accumulated dust, dirt and mineral residues.

Optimizing the performance of conveyor belts is within your reach!