Motorised belt cleaner

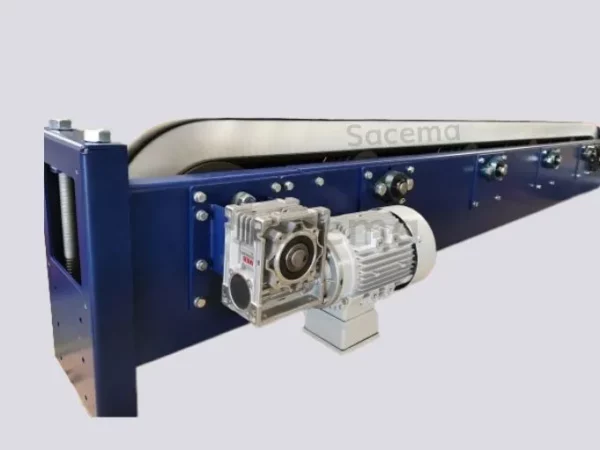

The Sacema Motorised Belt Cleaner is a specialised equipment for cleaning conveyor belts, by means of a motorised system, which has a cylindrical brush attached to it. This brush effectively cleans the belt, rotating in the opposite direction to the belt advance.

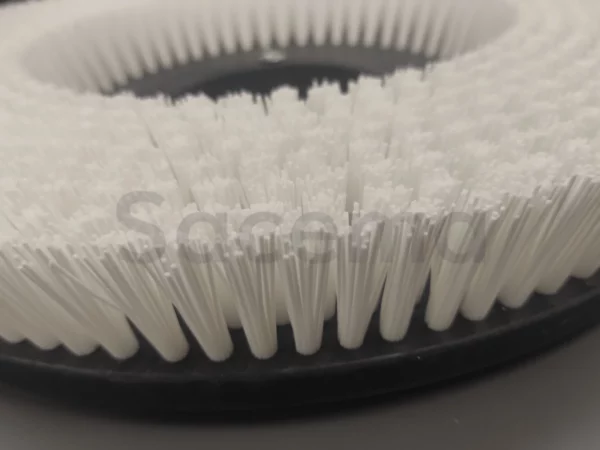

With the use of our cylindrical brushes, the Belt Cleaner provides optimal cleaning, improving conveyor belt performance.

At Sacema we have designed our Motorised Belt Cleaner to guarantee its high performance in industrial and logistic environments, where the cleaning and maintenance of conveyor belts are essential for an efficient and safe transport of materials and products.

The Sacema Motorised Belt Cleaner is an equipment designed for cleaning conveyor belts. Its components work together to ensure effective and safe cleaning:

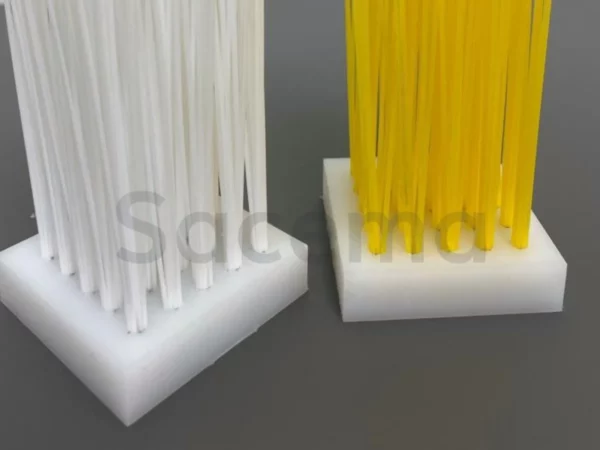

- Cylindrical Brush: Length equal to the belt width, with technical filaments.

- Steel Frame and Shaft: Standard anti-corrosion treatment or stainless steel for the food industry.

- Three-phase motor and reducer: Provides the nominal speed of the brush.

- Variable Speed Drive: Adjusts the speed of the brush by electric motor controlled by switch, potentiometer and emergency stop button.

- Mechanical Adjustment System: Brings the brush closer to the belt, optimising its use.

This set provides a complete solution for keeping belts clean and in good condition in various industrial applications.

If you have any questions about this or any other brush, please do not hesitate to contact us.

Sacema’s Motorised Belt Cleaner offers a compact, efficient and affordable solution to automate conveyor belt cleaning.

Compared to traditional scrapers, our system provides a significantly superior finish and efficiency. Scrapers offer basic cleaning, as opposed to cylindrical brushes, as they have a greater number of filaments rubbing against the belt surface, backed up by electric motor power.

In many cases, these methods complement each other; industrial rollers are placed after the scrapers in more demanding applications for an optimal finish. In addition, on ribbed belts, where scrapers are not feasible, cylindrical brushes are essential to maintain cleanliness.

Sacema’s Motorised Belt Cleaner stands out as a crucial solution in various industrial applications:

– Mining: Whether open pit or underground, this cleaner ensures effective cleaning on conveyor belts used in mineral extraction.

– Food Industry: In this sector, the cleaner finds multiple applications such as labelling, dedusting, and more, improving hygiene and process quality.

– Primary Manufacturing: Contributes to keeping belts in optimal conditions, avoiding interruptions in the production line.

– Heavy Mineral Extraction: For intensive applications, ensures belt cleanliness and performance in harsh environments.

– Ports and Bulk Areas: Optimises the cleanliness of conveyor belts in the movement of bulk goods.

– Conveyor Belt Installations: In a wide range of industrial environments, the cleaner ensures efficient and safe conveying by keeping belts clean.

This equipment adapts to multiple contexts, improving efficiency and extending the life of conveyor belts.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS