Spiral Brush

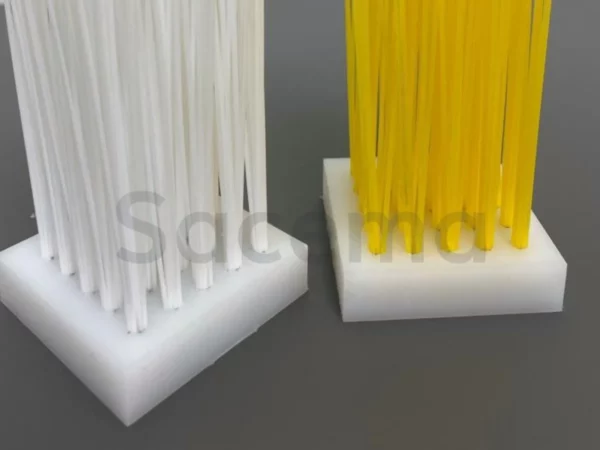

At Sacema we offer the spiral brush, a type of industrial brush that combines the characteristics of strip brushes and spiral brushes. It is made up of individual strips of filaments or bristles that are arranged in a spiral shape around a central core or axis.

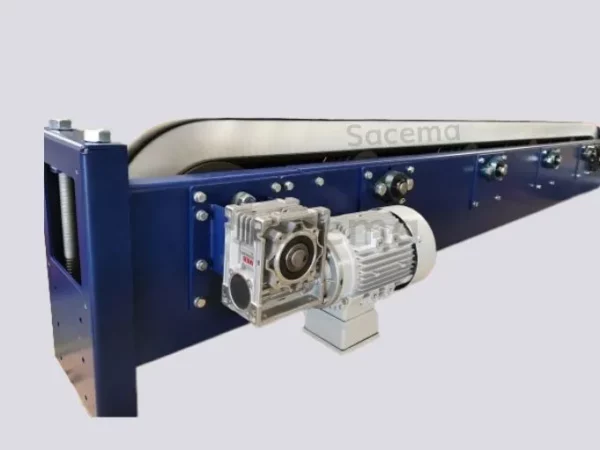

Sacema offers the Spiral Brush, a curved metal body strip brush. And our Spring Inserted Spiral Brush, commonly used in industrial applications.

Both allow great versatility with a very high cleaning capacity, thanks to their higher filament density.

If you have any questions about this or any other brush, please do not hesitate to contact us.

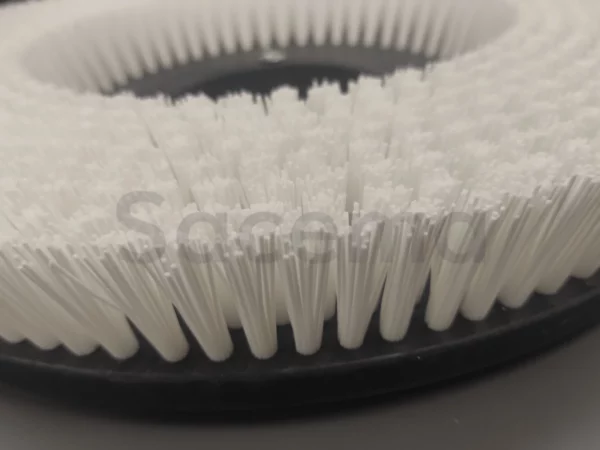

- Spiral brush

A spiral strip brush is a type of industrial brush that combines the properties of strip brushes and spiral brushes. It consists of individual strands of filaments arranged in a spiral configuration around a central axis. This design provides greater flexibility and conformability, allowing optimum contact with irregular surfaces and superior performance in applications requiring aggressive and precise brushing action in hard-to-reach areas.

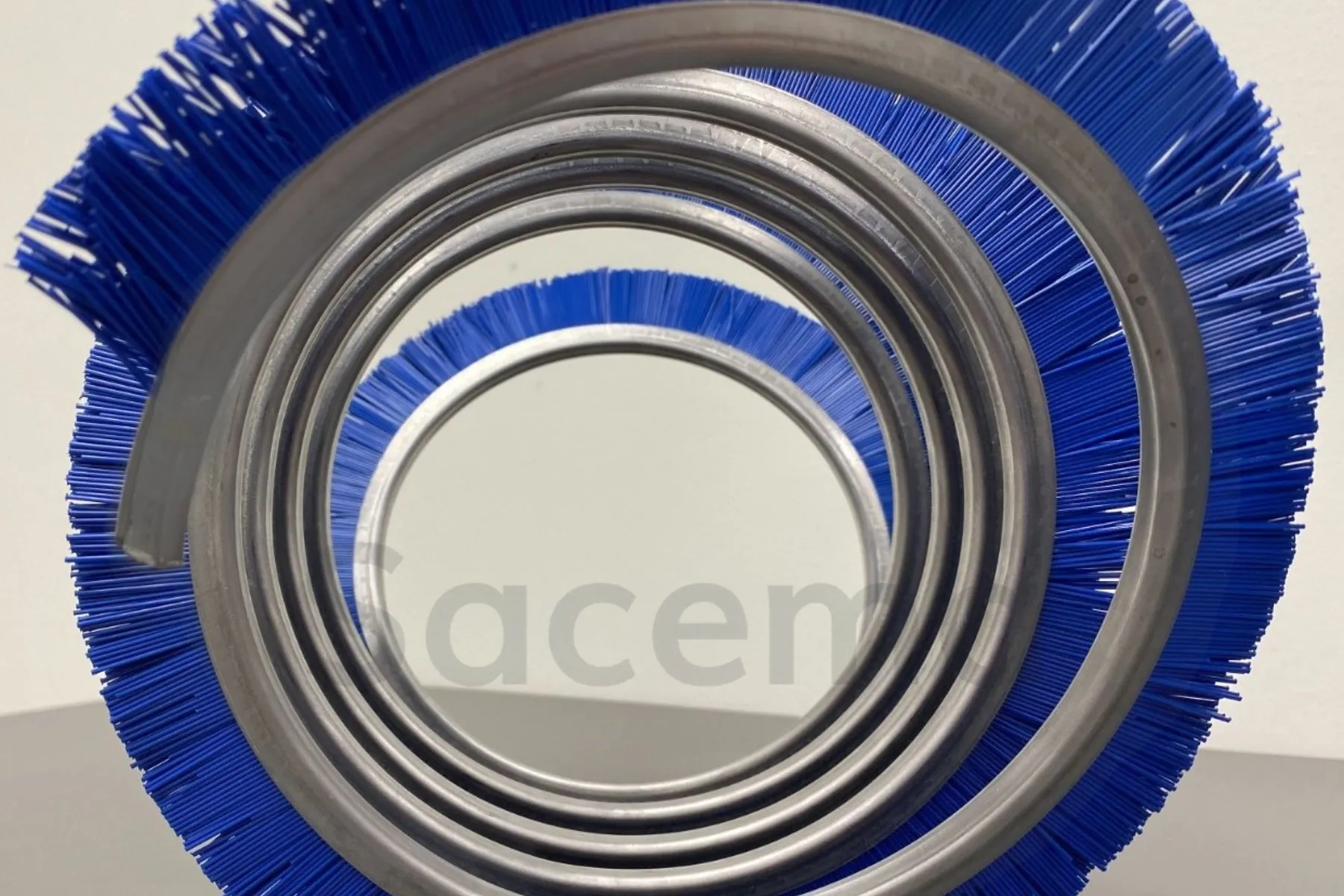

- Spiral brush on spring

A spring-inserted spiral strip brush is a type of industrial brush that combines specific features for increased cleaning and brushing efficiency. It consists of individual strips of filaments or bristles arranged in a spiral configuration, inserted over a spring core. This structure allows a flexible and adaptable brushing action on uneven surfaces, ensuring constant and effective contact during the cleaning process. In addition, the use of the spring provides a controlled pressure and elastic response that improves the performance and durability of the brush.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS