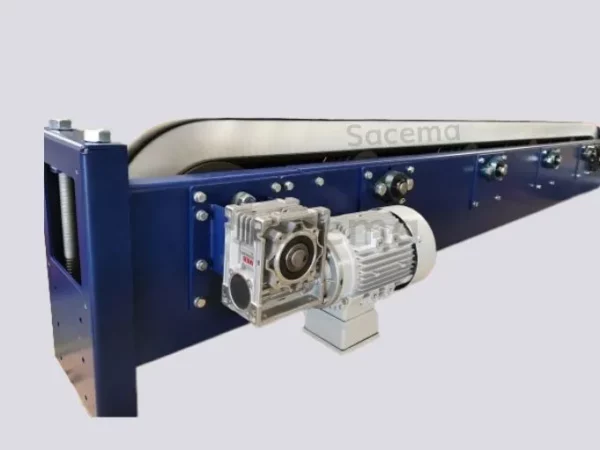

One of the services we offer at Sacema to make life easier for our customers is the maintenance of sweeping machines.

It is easy to neglect this important aspect of the machinery, but it allows it to give us a good service for longer, with fewer breakdowns and lower costs as it lasts longer without needing replacement.

Normally it is the manual that tells us the maintenance intervals for the machine, but in some cases we may not have a manual to refer to.

Procedures to follow for the good maintenance of the machines:

- A simple visual inspection often, to check for leaks and visible damage.

If any problems are found, it is best to take the equipment to a specialised mechanical service or to consult the maintenance manager.

- Grease all parts subject to friction: shafts, bearings, etc., as they are subject to the greatest wear.

Correct greasing of the shafts of our machine will result in less wear and tear and a longer life of the equipment. In the case of shafts that rotate at high speed, correct lubrication is vital to prevent damage to our machine.

- Check and top up machine fluids. For example, sweeping machines have an engine which, like a car engine, requires oil and anti-freeze fluid to operate.

It is therefore advisable to check these levels regularly to ensure that they do not fall below the minimum level.

In addition, if excessive consumption is detected, it is advisable to contact the maintenance service to avoid greater problems.

With these maintenance tasks we will prevent many breakdowns and save money and time.

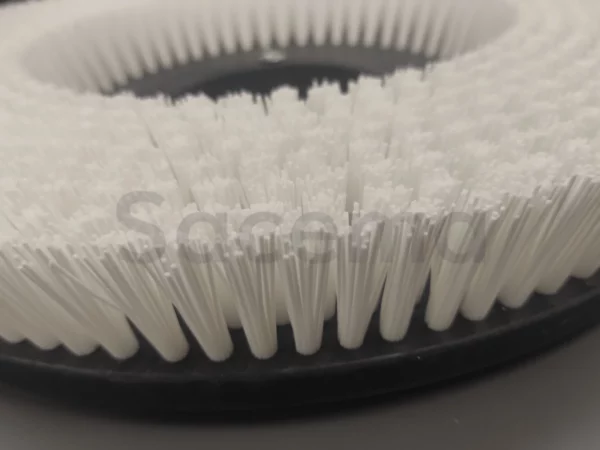

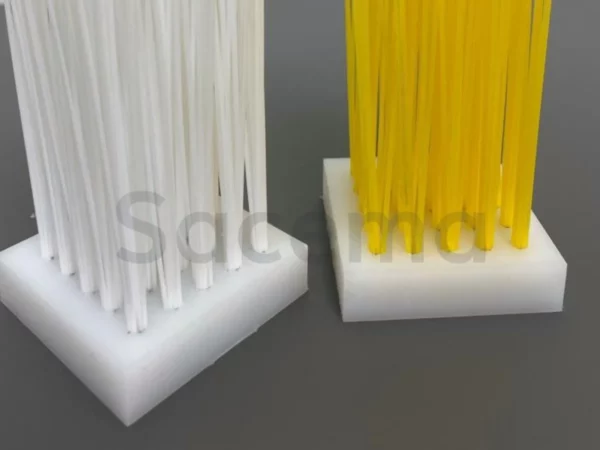

But when everything fails, at Sacema we have different street cleaning products for these sweeping machines and different spare parts for them.

For more information, please contact us.