The main goal of preventive maintenance is to maximize the efficiency of the industrial facilities, anticipating to unexpected eventualities. Is therefore none other than avoiding unforeseen stops and preventing accidents. Thus, it is possible to minimize the effects of abrasion in the machinery caused by the use and the passing of time, replacing the spare parts according to their number of working hours, independently of the degree of wear and tear they may have, following an ordered, updated, and controlled planification.

It is important to implement a realistic, efficient, and well-developed plan of preventive maintenance that meets the specific procedures and requirements. As well as grant it with the budget or the necessary resources in line with the activity the enterprise executes; this can influence directly to a cost reduction via the diminishing of standstills provoked by unexpected damages, the loss of the manufacturing capacity, and the extension of the machinery and the equipment’s lifespan.

The Preventive Maintenance in Food Industry

The operations of preventive maintenance are essential to the food industry, with a requirement level superior to the one of the traditional manufacturing industries. The adequate functioning of the activity in this area depends largely on the capacities of the people in charge of the maintenance management.

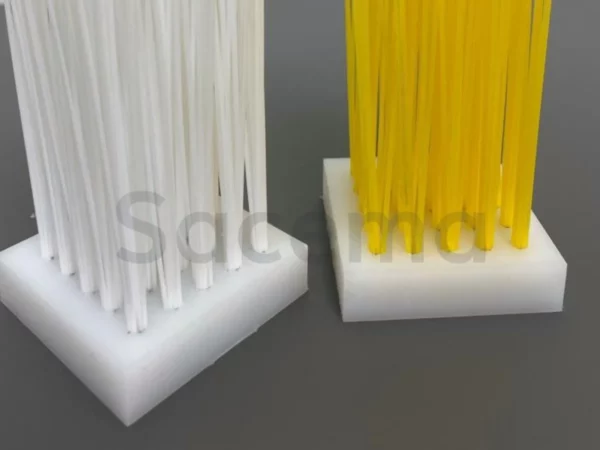

The plants of fabrication and the food-processing installations must fulfil regulations and standards utterly strict in terms of health and security. Consequently the components utilised in the machinery, tools and instruments must be certified compatible to the food industry by the FDA’s certificate.

In order to obtain this certificate, the food sector’s equipment must be fabricated uniquely in stainless steel and compatible plastics, as well as the machinery used to produce them must be applied only to this purpose.

To have a reactive response towards incidences not only can increase inactive periods of labour and delay the production line, but also jeopardize the compliance of regulations. Therefore, the technicians commissioned to this role inside an agri-food company, are also responsible for the quality of the products, as well as providing the working conditions are optimal and highly effective as the ones of the production process.

The Cleaning in Food Industry

One of the most important actions that must be included in a good plan of maintenance in the food industry is cleaning. The enterprises must follow perfectly defined protocols which must be known to every technician who participates somehow in the process. A good program of sanitation must guarantee a complete disinfection of the installations which encounter the food products. The objective is to combat the proliferation of microorganisms that may contaminate them or contribute to their deterioration.

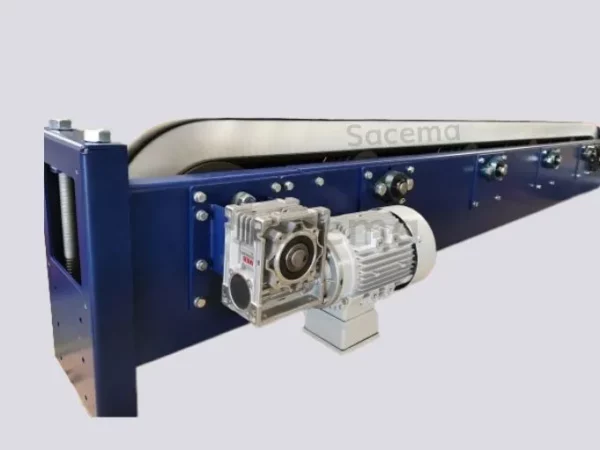

Preventing that conveyor belts, mixers, tenderizers, and other items accumulate dirt and food waste is key to the fulfilment of sanitary protocols, as well as the prevention of cross-contamination, and the contribution to prolong the lifespan of the equipment.

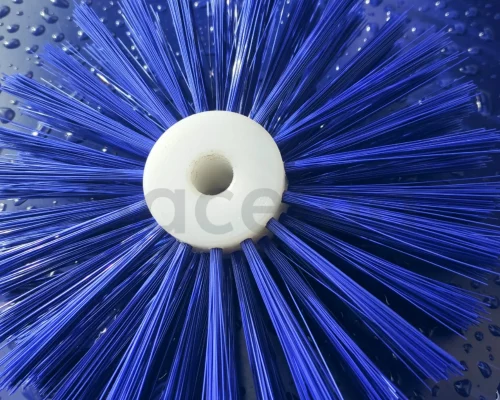

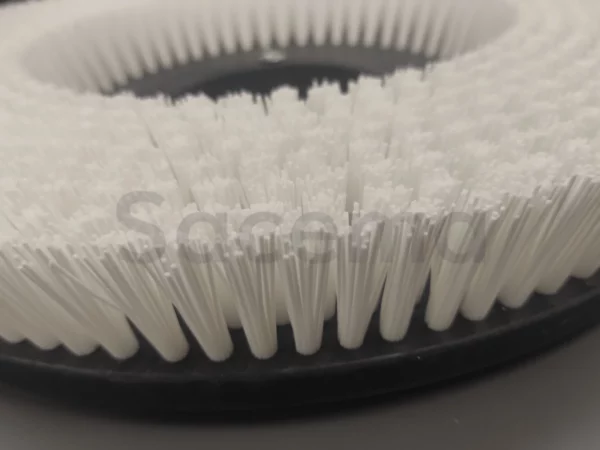

The industrial brushes serve to automatise processes of industrial cleaning and an endless range of possibilities since they are manufactured measured under a series of technical specifications. These replacements, generally cylindric and made of nylon fibres, adapt to every type of surfaces, and can reach the most inaccessible recesses. Their design facilitates too the evacuation of waste to obtain the desired results, as well as the reduction of cross-contamination, and the uncontrolled proliferation of organisms.

The Role of Artificial Intelligence

One of the clearest applications of the AI’s (Artificial Intelligence) algorithms is the predictive maintenance, because it is technology, in other words a software who predicts when, where and how will malfunctions be predicted, and is the one who leads the way to the preventive maintenance of all the manufacturing industries in general, especially of the food industry.

For the AI to generate trustworthy results, it must learn and feed with previous data about the behaviour of the machinery, the working conditions, and how the damages are produced. There are two ways of doing this:

- The first one is for the enterprise to have a data-recording system in plant, to harness the information stored structurally.

- The second one is automatic, no personal intervention is needed thanks to the IOT systems which are incorporated in the machinery, and which send operating data to the manufacturer in real time. With the passing of time, it generates an immense amount of information which nurtures the AI software, and it reimburses more accurate results.

Do not stop maintaining your agri-food industrial plants, especially with preventive maintenance; utilize technology for the latter and consider the industrial brushes to automate processes.