In this blog post, we will explore the fascinating world of cylindrical brushes and their crucial role in the food industry, with a particular focus on their application in candy production. From raw material cleaning to polishing and equipment cleaning efficiency, these brushes play a vital role in various aspects of the process.

What is a cylindrical brush?

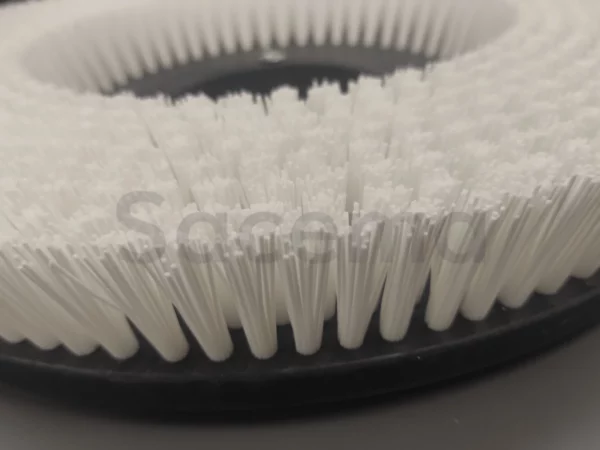

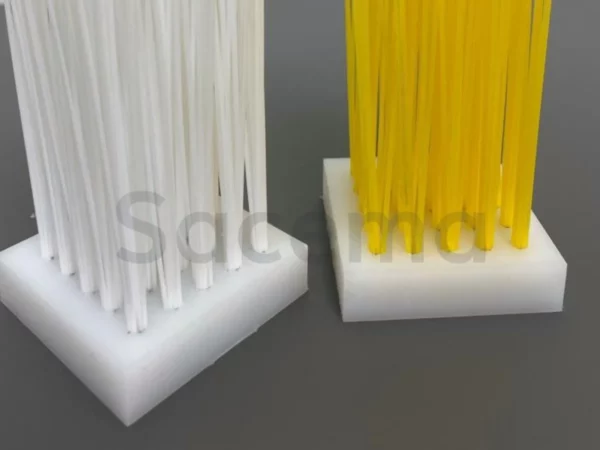

Cylindrical brushes are made up of a cylinder-shaped base, on which various filaments with specific characteristics are inserted according to the customer’s needs, and can even be suitable for the food industry. If necessary, we also manufacture the shafts for this type of brushes.

In addition, like the rest of our products, they adapt to the needs of each customer, giving rise to a wide range of sizes and shapes.

Thus, the cleaning needs are covered in a wide range of options. Do you want to discover them?

What are cylindrical brushes used for?

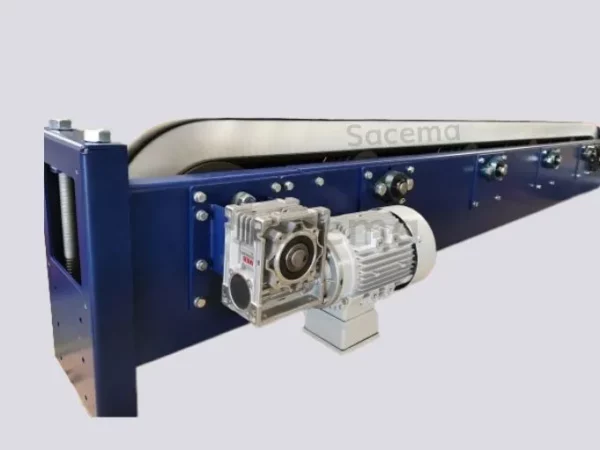

Cylindrical brushes find diverse applications in different sectors. Some of their most prominent uses include the cleaning of conveyor belts, the cleaning arm of solar panels, the animal comfort totem pole and the formation of roller conveyors. However, one of the areas where these brushes are most relevant is the food industry.

Cylindrical Brushes in the Food Industry:

Industrial brushes are found in multiple applications in the food industry due to their ability to perform cleaning, polishing and dusting tasks efficiently and effectively.

In particular, one sector where these brushes are widely used is in the candy sector. Have you ever wondered what the candy manufacturing process is like? Well, it is already clear to you that cylindrical brushes are used in some steps.

Many companies in this sector love our brushes and use them daily in their production.

Uses in Candy Manufacturing:

Cleaning of the raw material: prior to manufacturing, cylindrical brushes are used to clean the raw material, such as sugar, removing possible impurities or unwanted particles.

Shaping and polishing: during the shaping phase, cylindrical brushes shape the candies and polish their surface, ensuring a more uniform and attractive appearance. Caramels come in different shapes and sizes, so this is one of the most important procedures and thanks to it they get their shiny and flawless style.

Equipment and conveyor cleaning: these brushes are applied to clean conveyor belts, processing machines and containers that come into contact with the candies. This helps to maintain high hygiene standards and avoid cross-contamination.

Packaging: at the packaging stage, cylindrical brushes are used to clean trays, handling areas and surfaces where sweets are deposited before packaging, ensuring they are free of dirt or residues.

If you would like to find out more information about cylindrical brushes, do not hesitate to consult our website.