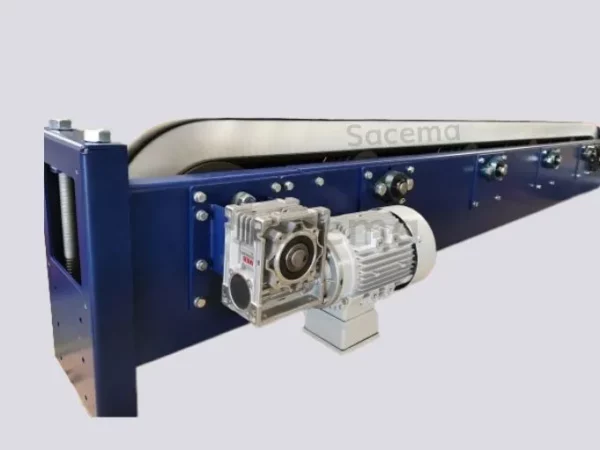

Although electric motors are more and more used in the automobile sector and fort this reason they are more in focus nowadazs, they have always been present in the industry for one of their greatest advantages: their reliability.

This reliability is mainly due to the low number of moving parts. Simplifying, one could say that an electric motor has two parts: the rotor and the stator. The stator comprises the housing and the rest of the parts that are fixed, such as the winding. The rotor is the rotating part. With the entire rotor attached, it rotates together with the shaft as one piece.

If we start counting the number of moving parts in a typical gasoline explosion engine, the number goes off. Four pistons articulated to their connecting rods and also to the crankshaft, two valves in each cylinder plus the components of the camshaft that moves them, a flywheel, bearings … not to mention the turbo or the belts that make all this turn synchronized .

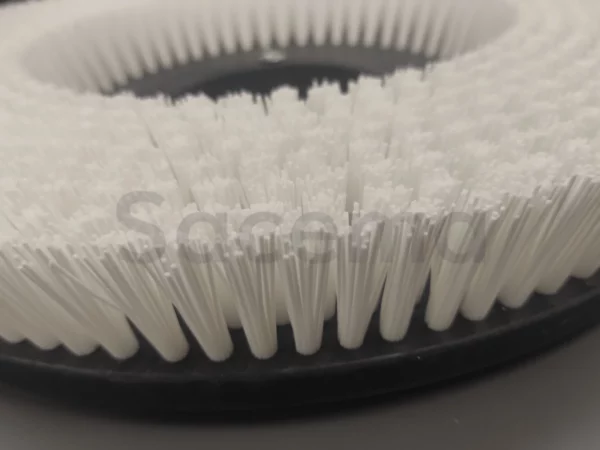

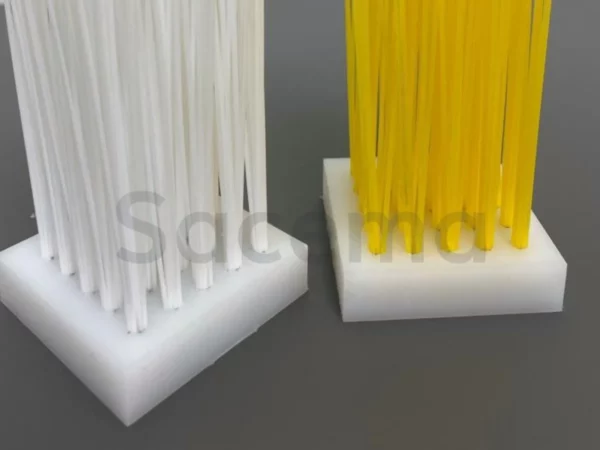

This is important because when moving the pieces wear out, as they rub against each other when turning. Electric motors have some limitations, but when they are not problematic they are often used in the industrial field (for example, some sweepers use them in their brushes) because it is more difficult for them to break down.