The Industrial Brushes are some of the most surprising components of industrial processes, due to their diversity of services and applications, and even today, the majority of professionals in the industrial sector are unaware pf them.

In Asturias, we have Sacema, which is a leader in manufacturing industrial brushes for labeling machines.

These labeling machines combine mainly three elements: the packaging, the adhesive and the label and most are composed of the following elements.

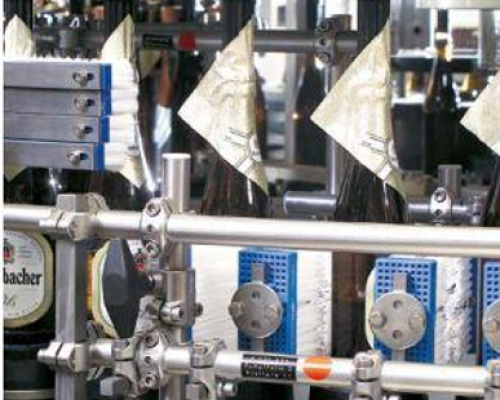

Figure 1-Industrial brush applying pressure on the label

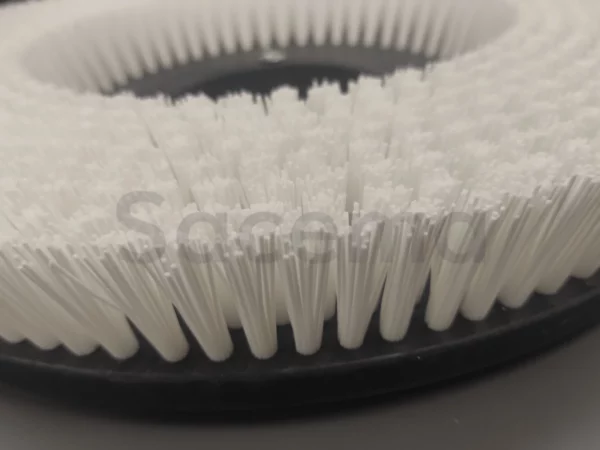

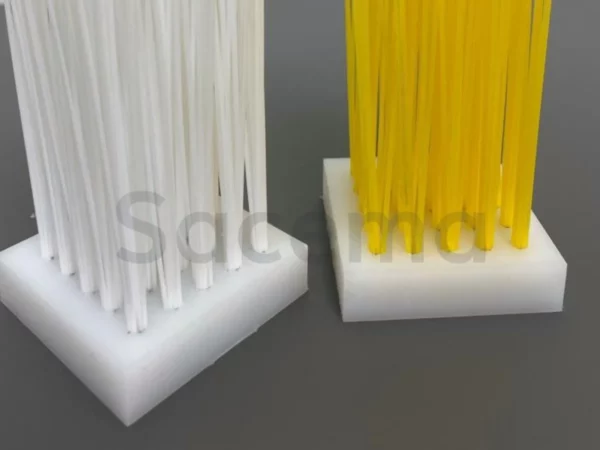

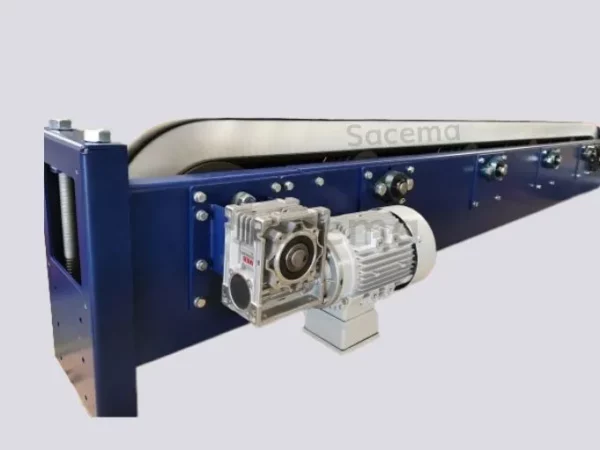

Figure 2-Elements of a labeling machine

The principle of operation of these machines consists of the following: the label feeder takes these to the adhesive scraper, and then to the glue cylinder where an adhesive base is applied to them, then be placed on the containers or bottles through of the labeling car.

Once the labels are positioned on the package, they slide along a mechanical belt that guides them through these industrial nylon fiber brushes whose function is to apply pressure to properly fix the adhesive and smooth the label.

Figure 3-Elements of a labeling machine

In the case of the labeling of some bottles, as can be seen in the following image, a set of brushes is responsible for smoothing and adhesive the main labels, while another set placed at the height of the neck of the bottle applies a smooth straightening to the smaller labels located over this area.

Figure 4-Two sets of brushes

In case you have a bottle labeling machine with industrial brushes, do not hesitate to contact Sacema.