The mining industry, as a primary extractive industry of minerals, requires large conveyor belts to transport minerals in large quantities and sometimes at high speeds to treatment stations. This demands equipment of substantial size and durability due to the rigorous operational conditions.

Conveyor belts are crucial elements ensuring the facility’s operation. Despite overflow areas to prevent blockages in preceding or secondary processes, their continuous operation and cleanliness are vital for mining operations.

It has been observed that at least 30% of unintended shutdowns in mining operations are due to conveyor belt malfunctions and operational issues.

Common problems with conveyor belts in the mining industry, applicable to other primary industries using conveyor belts, include:

- Belt misalignment

The belt deviates from its central position and moves towards one side, causing two main issues: material loss on the freed side and rubber friction with fixed parts of the belt. This is typically caused by misalignment in shafts and support drums of the conveyor belts.

- Roller jamming

Idler rollers rotate with the conveyor belt, and if a roller jams (often due to bearing failure from lack of cleaning and lubrication), it becomes a significant problem. If the main motor is strong enough, it can continue moving the belt but at a higher energy cost due to increased friction with the jammed roller, leading to premature wear on the belt or roller. If the motor cannot overcome the friction, an unintended shutdown requiring maintenance intervention occurs.

- Material loss

Despite material loss being common in long-distance transport, recurring losses in specific locations indicate potential issues. Material blockage at transfer points between conveyor belts causes similar problems to roller blockages.

- Belt slippage

Despite initial tensioning, belts gradually stretch during operation. This can lead to slackening in tension, causing partial or complete slipping on the drums and resulting in significant friction.

- Corrosion of elements

Environmental agents, lack of protection, or chemical incompatibility between materials and transported substances commonly cause damage that manifests gradually and, if not addressed promptly, leads to severe breakdowns over time.

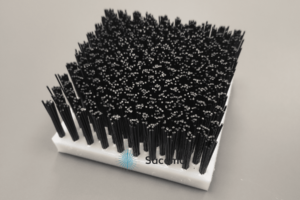

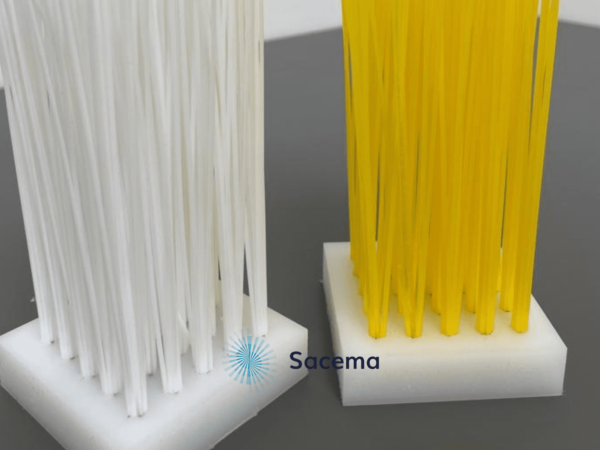

- Lack of return cleaning

Mining conveyor belts incorporate equipment like scrapers or brushes in the return to ensure all transported material moves to the discharge stream or transfer station at the belt’s destination. Inadequate cleaning or defects in cleaning equipment lead to material being dragged back along the belt return, causing:

- Material loss, reducing mining production.

- Increased cleaning needs around the belt, accumulating material that requires periodic removal.

- Damage to rollers, where material adheres, causing them to enlarge in diameter due to sintering, leading to future misalignments or roller damage.

- Damage to the belt itself, as adhering material may sinter under high pressure, affecting its future operation.

Methods for cleaning mining conveyor belts include various types of cleaners that complement each other, such as scrapers and motorized brushes. The most effective approach is to use both traditional scrapers for coarse material and motorized brushes for fine material, achieving balanced cleaning of mining belts.

In conclusion, inadequate maintenance or malfunctions in a conveyor belt can have a significant economic impact on the mining industry due to the high volumes and operational demands of these plants. Regular inspection, lubrication, cleaning, and maintenance of mining conveyor belts are essential, along with integrating efficient belt cleaning equipment like traditional scrapers and motorized brushes to ensure optimal cleanliness and efficiency.