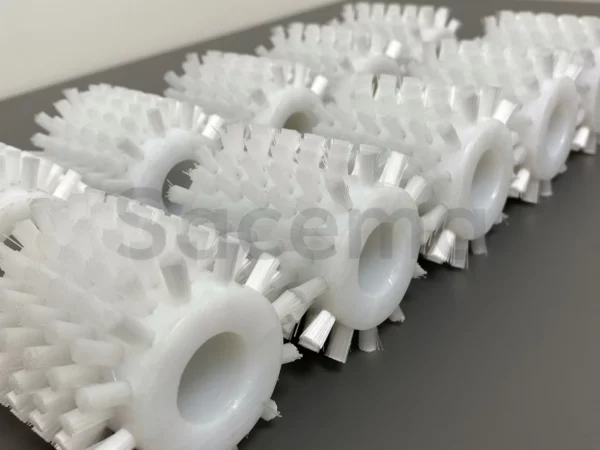

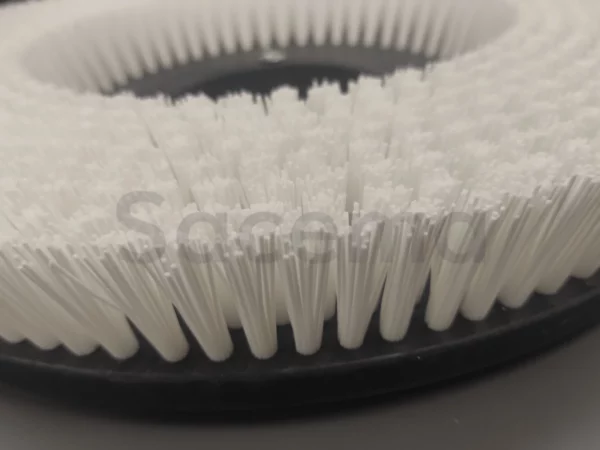

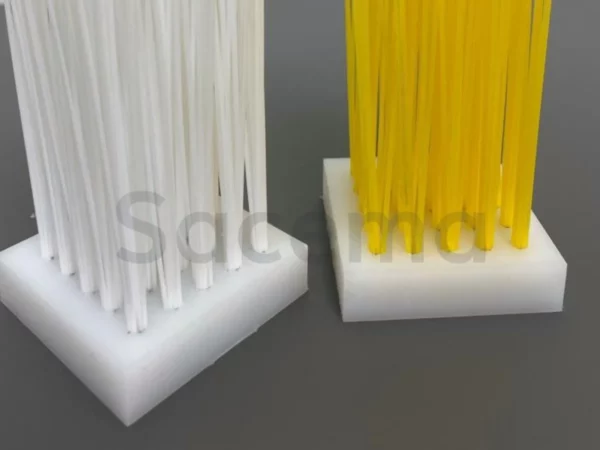

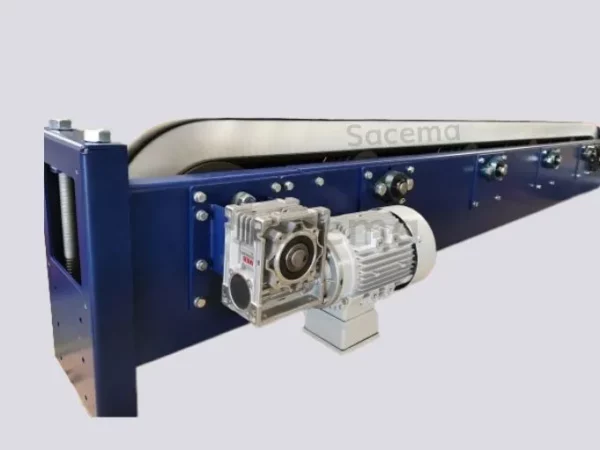

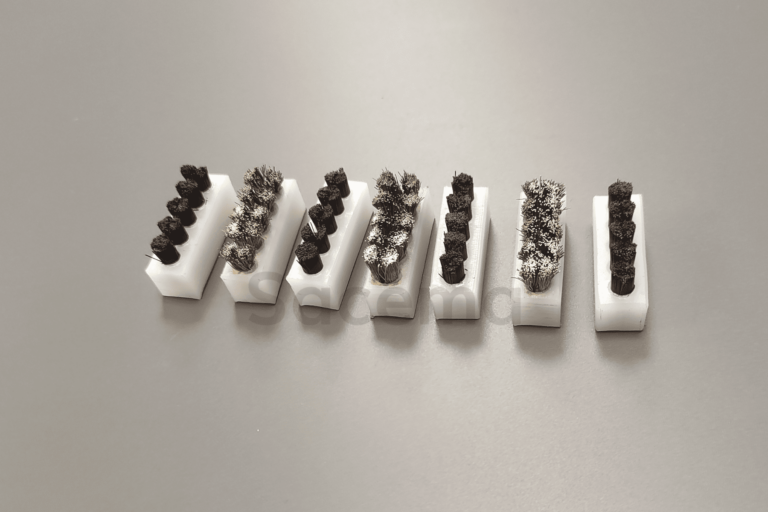

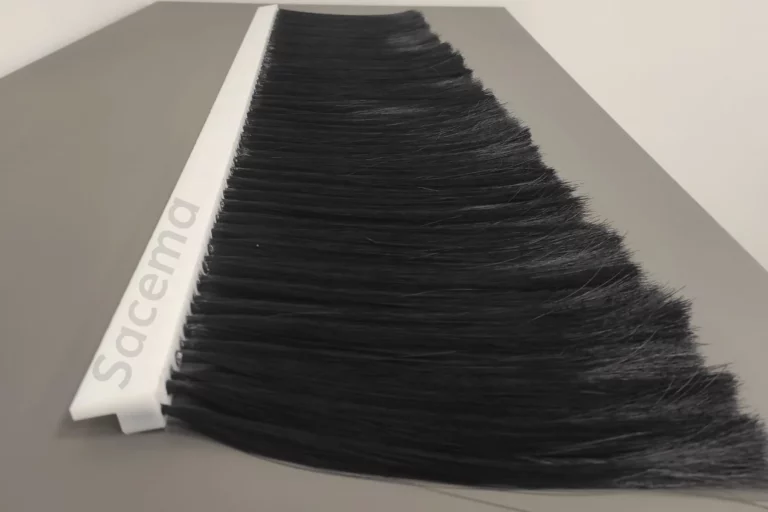

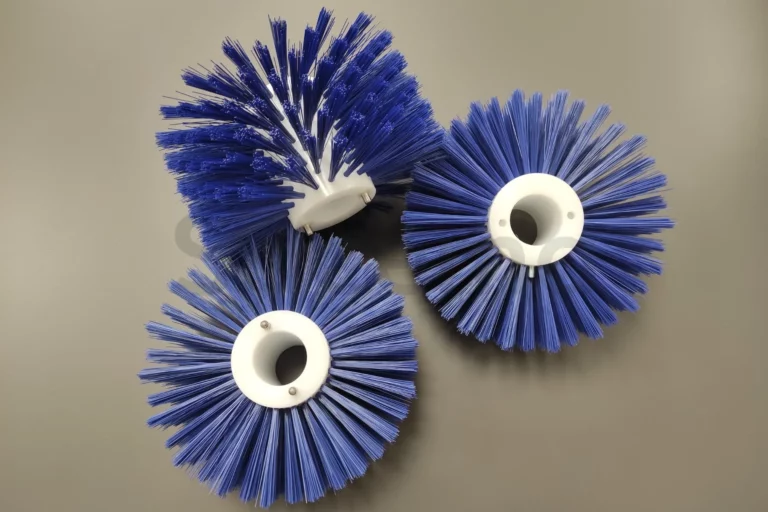

Industrial brushes

[f_sectores_acf] [f_aplicaciones_acf]

At Sacema, as manufacturers of technical brushes, we specialise in the manufacture and development of designs related to the automation of cleaning processes, most of which include our made-to-measure Industrial Brushes.

We manufacture Industrial Brushes to measure, adapting them to every need.

We manufacture Industrial Brushes to measure, adapting them to every need.

We are dedicated to the manufacture of customised industrial brushes to meet the specific needs of each customer.

If you have any questions about this or any other brush, please do not hesitate to contact us.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.