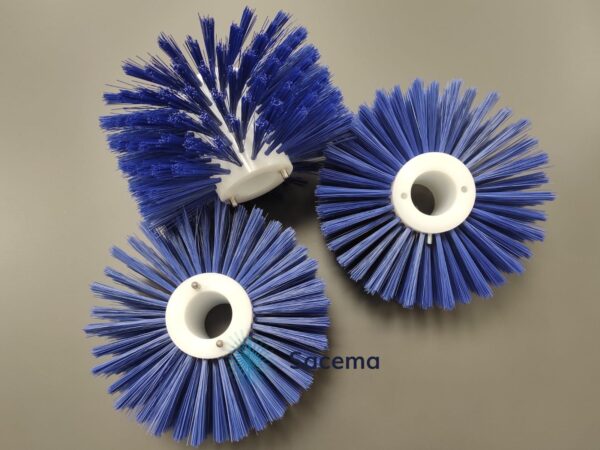

Lath and Table Brushes

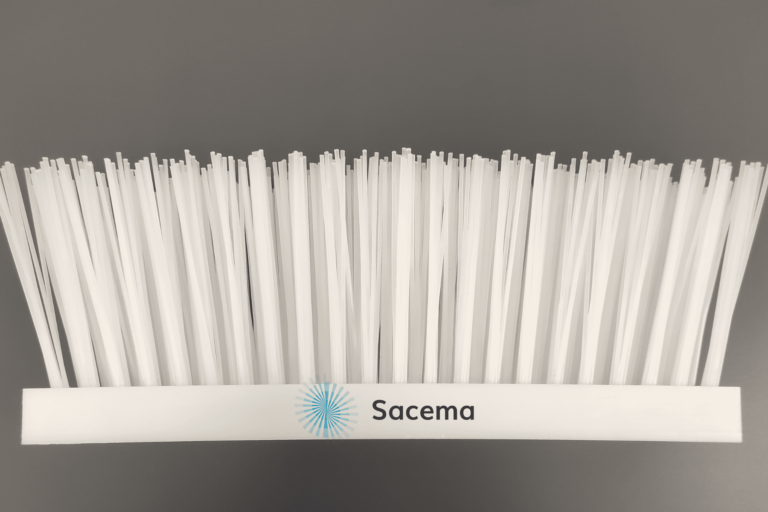

Lath and table brushes are a type of brush shaped like a strip, plate, or ribbon that is manufactured from a flat body, typically obtained by cutting flat plastic plates

Due to this lath and table shape, they are designed to be mounted on flat surfaces and generally in static applications (with some exceptions, when these brushes are mounted on robotic equipment or equipment that moves, where the brush moves in solidarity with its support).

It is a very versatile product, widely used in all types of manufacturing industries, for cleaning tasks, product separation, gap sealing, labeling, limiting the movement of parts, supports for sheet metal forming machines, applying surfaces, etc.

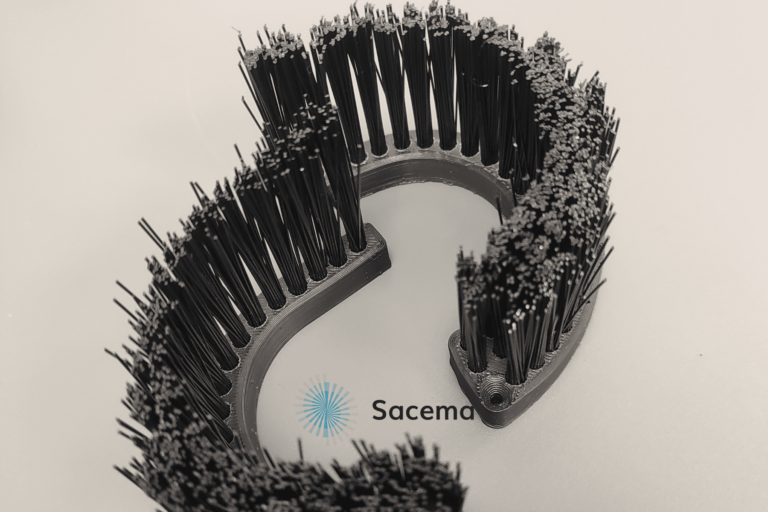

Like other types of industrial brushes, lath or table brushes are custom manufactured according to customer specifications and needs, especially when recesses or curved shapes are required to adapt to the geometry of the machine where they will be installed.

Lath or table brushes are integrated like other solutions:

- Protection and support tables.

- Static band cleaner.

- Attached to large diameter tubes to form circular brushes.

- Belt brushes, which despite their separate distinction, are still based on flexible belt strip brushes.

Finally, the method of dragging or fixing the brush to its support must be defined, which can be done through screws, rivets, or any other method that ensures a secure and efficient attachment to the brush support.

Often, recesses and fittings are machined into strip, lath, or table brush bodies to facilitate integration with supports, and it is not uncommon for them to come with pre-machined fixing holes or slots.

Sacema manufactures bodies using CNC machines and uses 3D CAD tools for their definition.

If you have any questions about this or any other brush, please do not hesitate to contact us.

There are several types of table or lath brushes, depending on the shape of the base plate used:

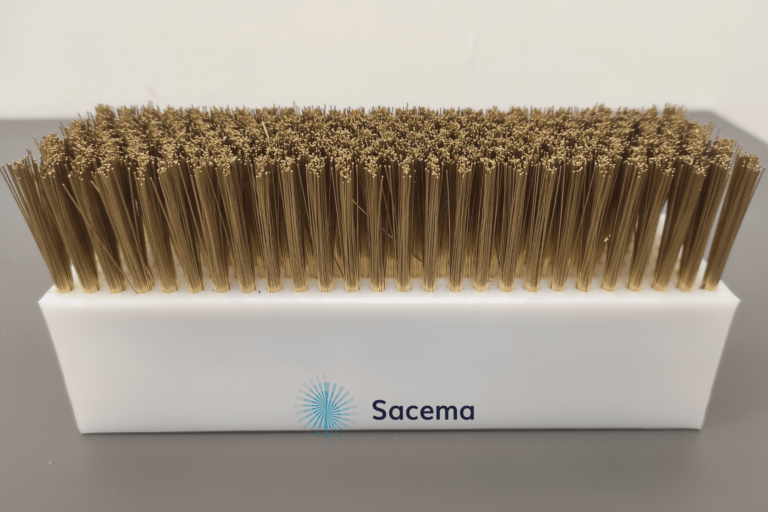

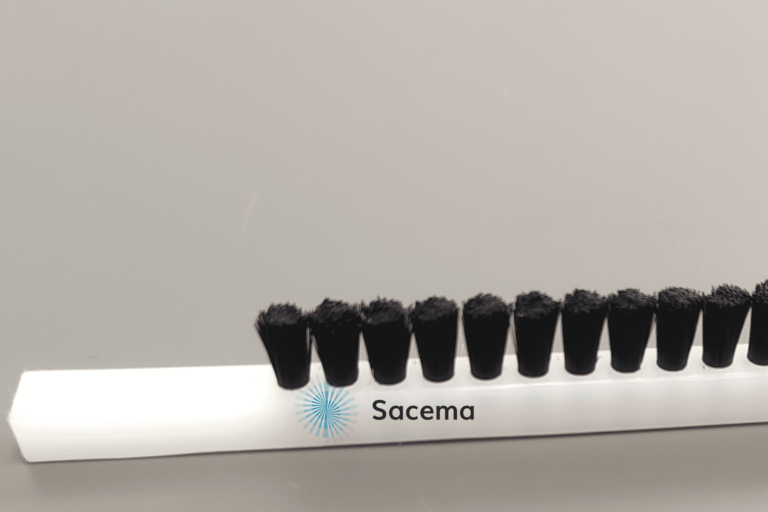

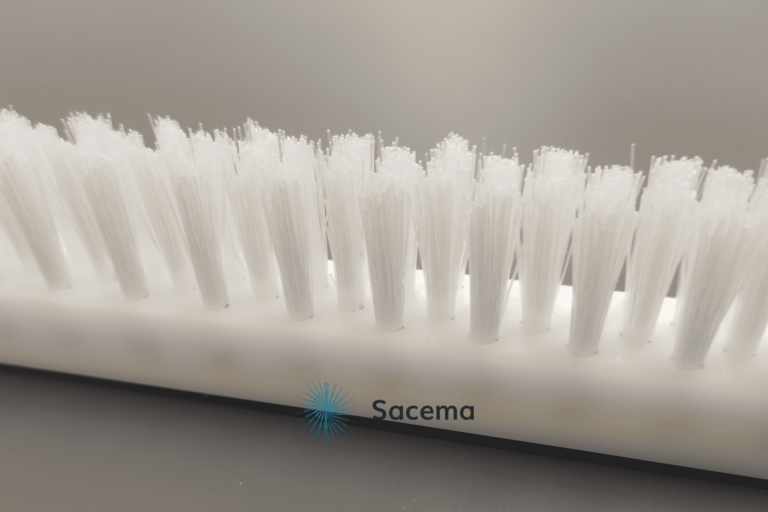

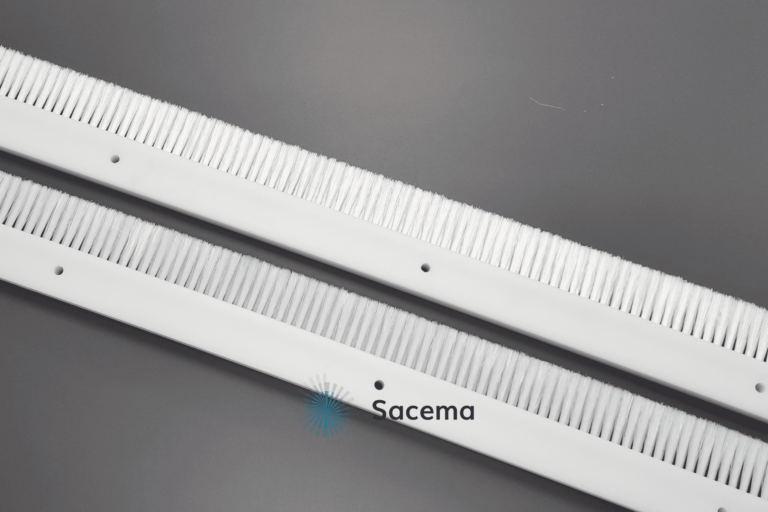

- Straight strip brushes. These brushes have a slender, elongated rectangular body. Due to their slimness, they tend to be somewhat flexible when the plate thickness is reduced.

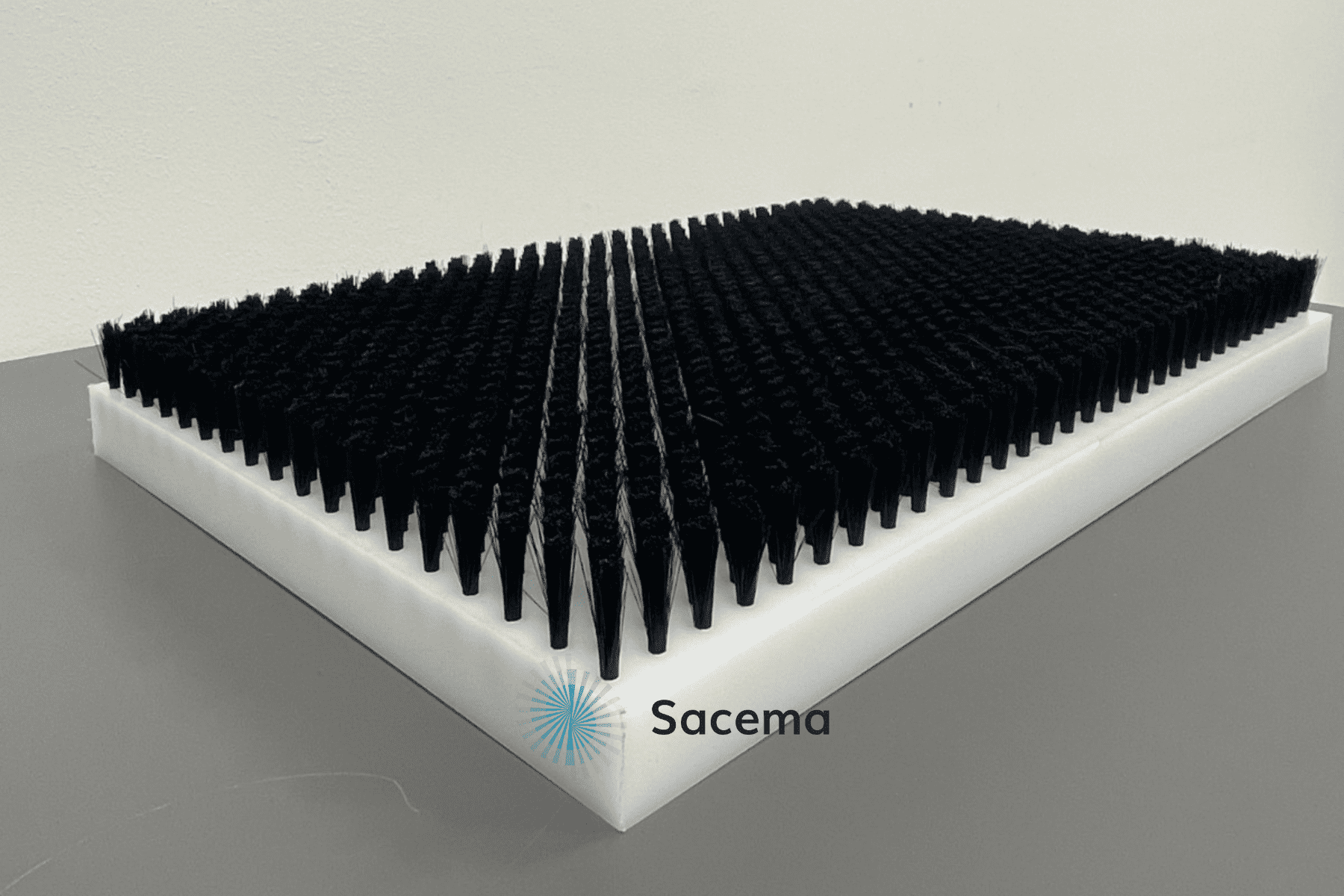

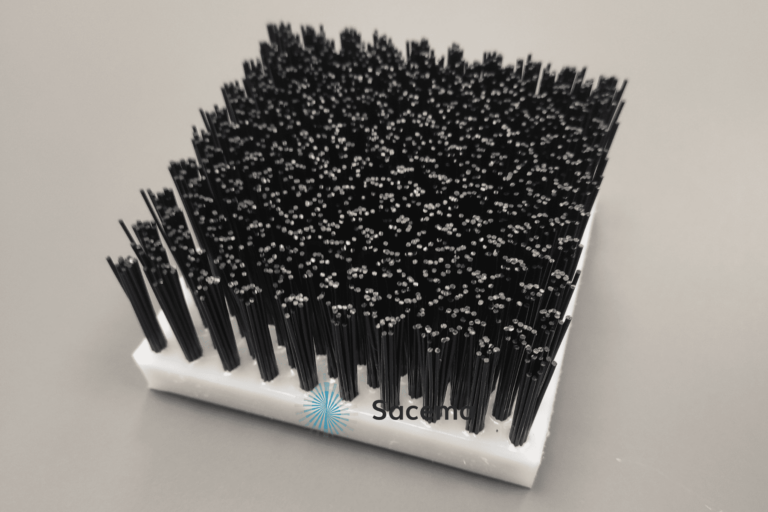

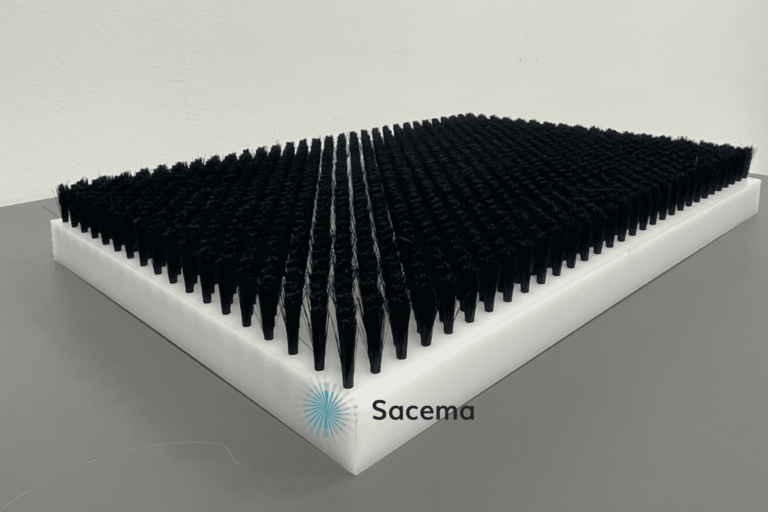

- Plate or table brushes. This is a variant of the former where the working surface is larger and acts like a plate, thus being a much more rigid equipment than the former.

- Strip brush with support. It’s a strip brush where supports, fins, and brackets are machined so that the brush is easily integrated into machines.

- Special-shaped plate brushes. These are brushes with curved shapes and interior voids, machined according to specified geometry and completely customized.

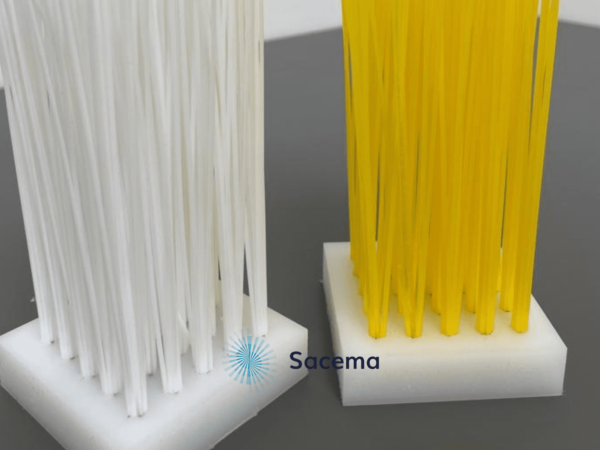

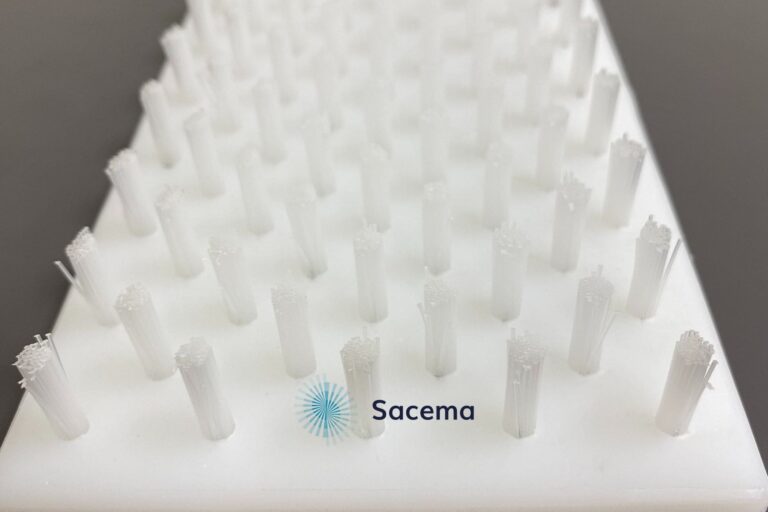

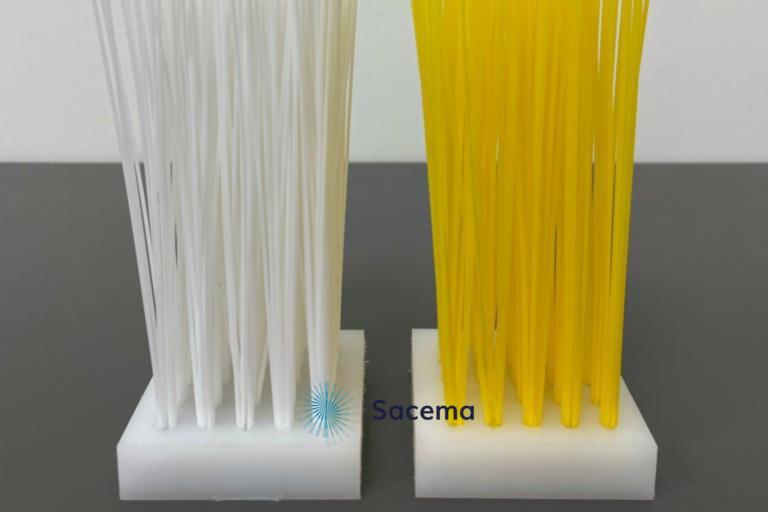

The shape and distribution of the filaments are much simpler than cylindrical brushes, as the goal is solely to cover the strip or plate surface with filaments, optionally varying their density.

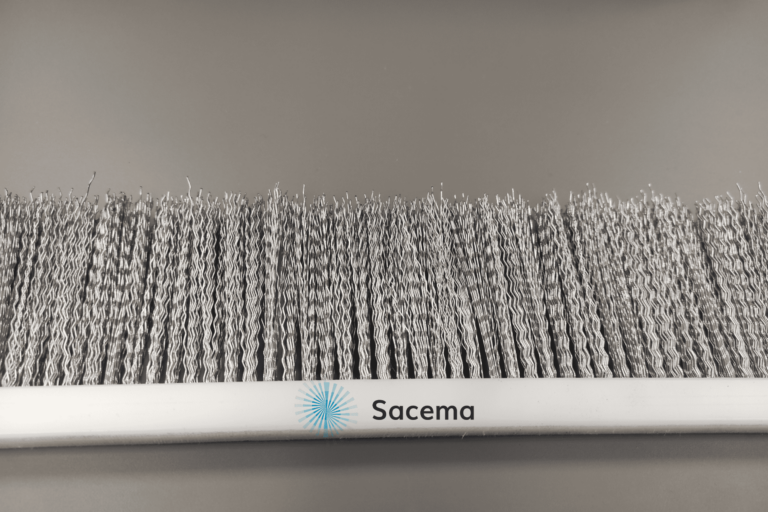

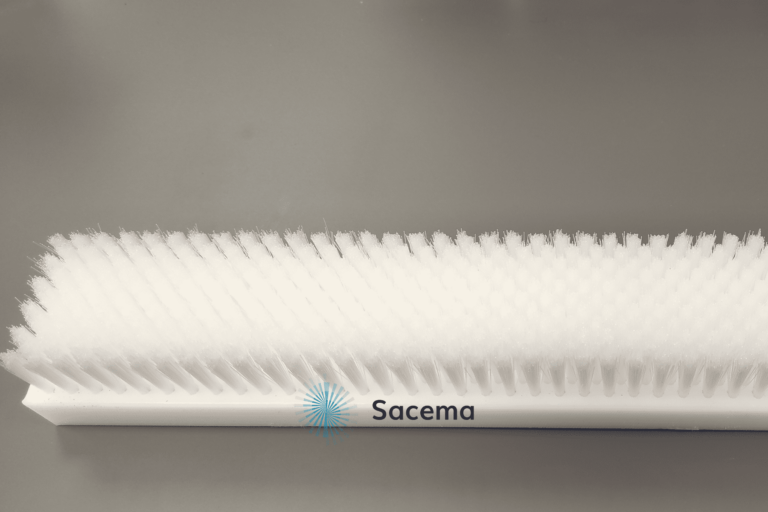

The arrangement can vary between staggered or parallel rows. Similarly, it’s common for tufts to emerge at a longitudinal angle to cover more than just the length of the support, although in many applications all filaments are inserted at the same angle for directional guidance or application on the working surface.

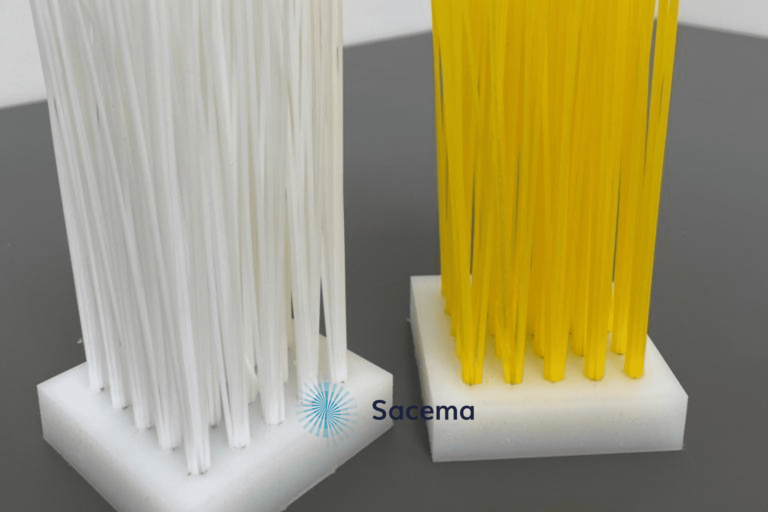

Technical table or strip brushes, like other industrial brushes, can be defined with synthetic, natural, or wire filaments.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS