Antistatic Brushes

The antistatic brushes are brushes in which both the body and the filaments are made of materials with high electrical conductivity, seeking the derivation of electrostatic charges with a flexible contact.

Electrostatic electricity in the manufacturing industry, generated by friction between surfaces, causes major problems and accident risks, which are solved with antistatic brushes.

Static electricity brushes are still brushes that neither brush nor perform any superficial work, but their only and important function is to be a very good electrical conductor.

For this, both the body and the filaments must be very good conductors of electricity, and their shape is generally a straight strip (similar to a strip) or also an anti-static wick integrated into a quick-connect faston.

The main purpose of installing antistatic brushes is to create a flexible and wireless contact between the surface to be grounded and the grounding points of the installation, since in many processes that generate static electricity in the industry, it is not possible to put these parts in direct contact with the machine frame or grounding terminals.

Antistatic brushes must, in turn, be connected to the grounding point of the installation to perform their complete function, which is to derive the electrostatic electricity generated on the surfaces, which passes through the antistatic brush, and from there it is derived to ground through the electrical wiring.

The most commonly used antistatic brush is a strip of 1 meter in length, 15 mm in height, and 2 mm in thickness in aluminum, which is mounted by deformation (no staple set) with filaments either of carbon fiber or braided stainless steel wires, also 15 mm in length to make a total height of 30 mm.

A similar support is also often used but with a flap to facilitate its assembly, very similar to the aluminum support of a strip brush.

In essence, by using a brush that has both the body and the filament as an electrical conductor, you already have an antistatic brush, and it is very common to use strip brushes with metallic wire as a brush for deriving electrostatic charge.

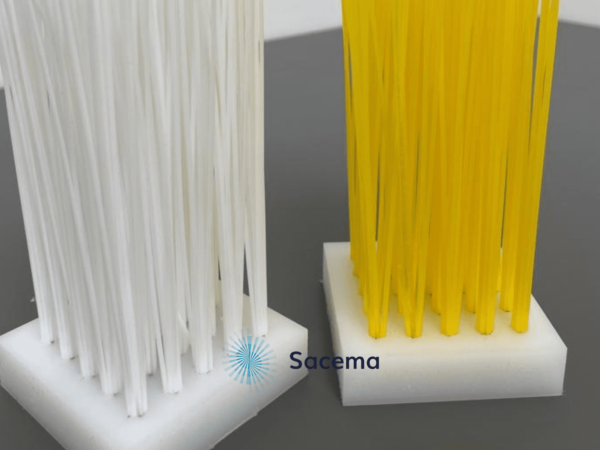

Increasing the technification of the brush, there are conductive plastic materials (both the bases and the filaments) used in special applications. The filament used in this case is a high-performance metal-charged polyamide 6, making it conductive to electricity, with behavior very similar to that of classic polyamide 6, and is available only in black.

If you have any questions about this or any other brush, please do not hesitate to contact us.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS