HEAVY DUTY Motorised Belt Cleaner

The HEAVY DUTY motorised belt cleaner, the version of the belt cleaner designed for heavy industry, requires reinforced, stronger, and high-performance equipment due to the demanding application.

The HD or heavy-duty belt cleaner is the high-demand version of the cylindrical brush unit, designed for heavy industries such as mining or steelmaking, i.e., primary processing of large quantities of raw materials.

Due to the high demands of these industries, this product features larger, stronger, and more resistant components, with the following characteristics:

- The supports incorporate more reinforcements than standard, and the minimum steel sheet thickness is 10 mm, compared to 5 mm for sheets in the standard version of the belt cleaner.

- The shafts are always hollow tubes, and the shaft tips at the ends are 35 mm instead of the standard 25 mm.

- Bearings are UCF type, 35 mm instead of the standard UCFL 25 mm.

- The gear motor has a minimum power of 3 HP compared to 1 HP for the classic cleaner.

- Height adjustment screws are M30 instead of M20 in the standard.

- Incorporates lifting and load handling elements.

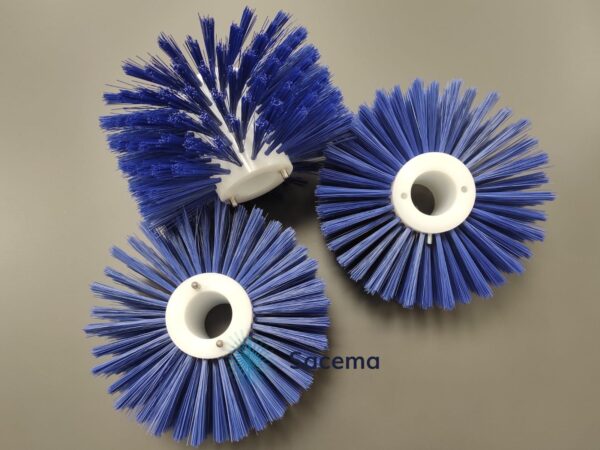

- The cylindrical brush has a minimum diameter of 350 mm, customized according to the working shape.

- Brush change system without dismounting the mobile support.

Due to its highly demanding nature and the type of industry in which it is installed, it is common to customize the anchorages and shafts according to the dimensions of the cylindrical brushes incorporated into the HD cleaner.

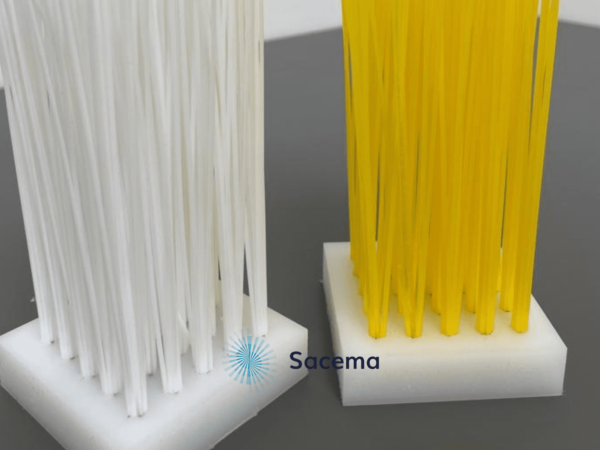

Similarly, this type of industry has very high operating and maintenance costs, so the brush’s lifespan must be longer than usual, and it typically uses higher-performance filaments than other industries. Additionally, it incorporates additional plates to facilitate brush replacement without needing to dismantle and remove the shaft opposite the motor and transmission.

The motor is controlled by a speed controller that is added externally, allowing adjustment from the motor reducer’s maximum speed of 285 rpm to the appropriate speed for the process.

Moreover, it is common to complement this with automation of the cylindrical brush’s working position, as heavy-duty industrial processes often involve varied surface geometries to be brushed.

This height adjustment system replaces both threaded brush positioning spindles with ball screws at the ends, motorized to position the cylindrical brush of our heavy-duty belt cleaner precisely where needed, aided by a position encoder and instrumentation and control system.

At Sacema, we have the material resources, technological tools, and trained human resources to develop the comprehensive turnkey project for the HD belt cleaner, including its customization design, manufacturing, installation, and commissioning with the necessary instrumentation.

For any questions or inquiries about this or any other brush, please do not hesitate to contact us.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS