Maintaining industrial cleanliness in the factory is not only important in terms of aesthetics and the quality of the working environment, but also has a direct influence on the development and efficiency of the activities carried out in that environment.

Over time, machines or tools have been built that have made it easier for these industrial cleaning tasks to be carried out more quickly and with the need to invest fewer resources, so that, in the end, it is cheaper for companies.

In this sense, the interior cleaning of pipes is key to favour the correct circulation of both gases and liquids, but until now it has had a problem: how to adapt to the turns of the elbows?

A practical and innovative solution

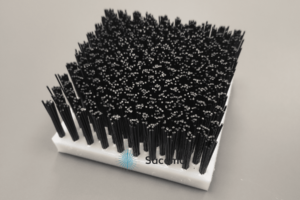

For the time being, conventional rigid brushes were used that only allowed cleaning in straight sections. However, Sacema has developed a solution that is highly adaptable, both dimensionally and geometrically. This solution is based on flexible body brushes mounted on springs, which, with threads at the ends, allow them to be dragged in both directions of the pipe, thus carrying out the cleaning.

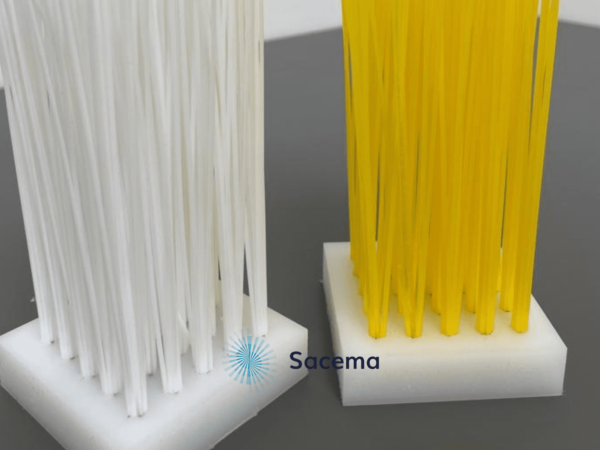

The filaments are based on strip brushes curved to the size of the spring. This means that a wide variety of materials and filament densities are available. At the same time, by varying the exit of the filament from the strip itself, the final diameter of the product changes, thus having a wide range of possibilities available to the customer.

Description of our product

The spring is of an industrial nature and provides body, stability and flexibility to the spiral strip brush. Female ½”G free threaded fittings are welded to it, which have to be specially machined so that they can be effectively integrated into the ends of the spring and so that the user is able to thread an element that makes him pull from both sides, so that the spiral strip brush on spring passes easily through the inside of elbows and complex turns in pipes.

On request we can customise fittings with other threads or male instead of female, but the standard is a ½”G female in stainless steel.

The spring used as a base is also stainless steel, and can be made with any coil brush filament, whether synthetic, natural or wire, although the majority of brushes made are either synthetic or made from carbon steel wire or stainless steel wire.

The synthetic brush is for simple superficial cleaning, which should be accompanied by degreasing or descaling agents, but when aggressiveness is required, it is necessary for the spiral to be made of carbon steel metal wire in normal pipes or stainless steel in stainless steel pipes.