There are different formulas for cleaning the renewable energy installation, depending on the country where it is located, the solar panel installation, the ease of access to water, the purchasing power of the owner, the salary cost of the cleaning operators, the cost of fuel and maintenance of the machines, the way in which the renewable energy is generated, the location and especially the size, all these factors must be weighed up when choosing the cleaning system.

And it is already in the assembly and not after commissioning, which is also the time when cleaning starts, since it is necessary to start measuring, testing and drawing the first conclusions.

According to the different sources you can consult, the performance of dirty photovoltaic panels and trackers down up to 20% compared to a solar panel on the next panel that has been cleaned beforehand.

The first thorough cleaning is carri bed out right at commissioning for handover to the customer and owner of the solar farm, and from then on, it is up to the operating service to determine the degree and frequency of solar cleaning, or in other words, the minimum level of cleaning required, in order to define the maintenance and cleaning plan for the solar farm.

The method of cleaning the solar panels should be defined in the design of the solar farm, as methods using heavy, high-performance machinery require spacing and spacing between panels, which does not require manual cleaning.

Therefore, the maintenance and the cleaning of solar panels is a priority issue to be addressed before starting any renewable energy project.

The cleaning system can evolve as the needs and operation of the solar farm change, but it must be studied and defined at the time of project definition and design.

How to clean the solar panels in a solar farm?

1. Manual cleaning of solar panel.

This cleaning is handmade work, cleaning the panels like any other window in a building, using brushes similar to the brooms used to clean vehicle windscreen wipers with poles and plenty of water.

They have the advantage of being cleaned with the minimum investment, with very low energy expenditure, of being very flexible, and of being able to project the installation with very small aisles, but the disadvantage is more than evident: it is the cost of the personnel due to the fact that many people are needed, since it is a very slow process, and with a lot of water expenditure.

This system is used in very small photovoltaic farms, especially in self-consumption parks, SMEs and neighbourhood communities.

Manual cleaning is also necessary in very old solar farms with very narrow aisles where there is not enough space for access to heavy machinery, or in those located in countries where labour costs are very low.

In countries where the cost of labour is significant, and the solar park reaches a certain size, the use of cleaning machinery becomes essential to achieve performance.

2. Cleaning of solar farms using pressurised water machines.

This is a variant of the previous one that incorporates incipient machinery, although it is very simple. A water tank is usually installed on a trailer, with its combustion generator to feed energy to a pressurised water pump.

An operator manually cleans the solar energy panels with the pressurised water gun.

It is a cleaning system that has similar advantages and disadvantages to the previous one, although it provides more performance and, depending on the skill of the operators, more or less water consumption.

It is important to point out that the first solar panel cleaning system consumes external energy and must therefore be quantified.

3. Motorised solar panel cleaning systems with light machinery.

These are technological cleaning systems, even if they are lightweight. They are placed on the solar panels and clean by mechanical brushing. At least one person is needed to accompany them, providing the energy supply and water, and they are moved by hand from one line of solar panels to another.

It is a device that works in a similar way to the scrubbing machines that you can see in supermarkets and shopping centres, with their scrubbing brushes.

It may be practical for small installations or large self-consumption areas, but it is too small for large installations.

The investment required is not insignificant, and there are various equipment on the market, more or less technological, with a very acceptable and exceptional finish.

They have the disadvantage of being inoperative in those solar farms that have several rows of panels together, or in solar trackers or in the reflector panels, but in most photovoltaic installations, one or two rows of panels can be one of the best options to carry out the cleaning of solar parks.

4. Solar field cleaning systems with heavy machinery.

Cleaning systems with heavy machinery for solar installations are the most common in the most developed countries, where labour force is more expensive, and where larger solar farms are installed, which need to be kept clean to provide greater performance and make it essential to have a competitive solar panel cleaning system, both in terms of cost and working time.

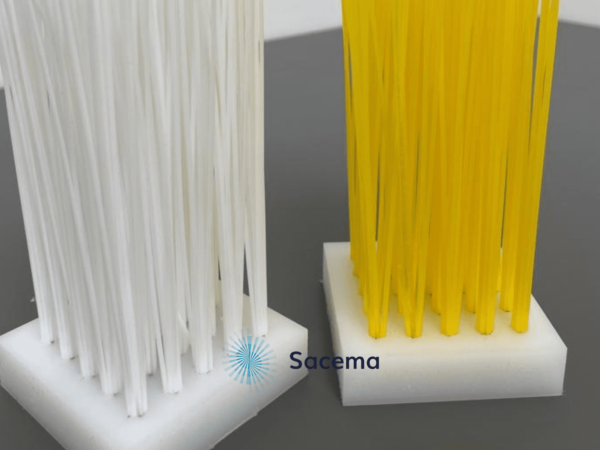

At Cepillos Sacema, we have designed and developed a brush for cleaning this type of solar farms.

This cleaning system, broadly speaking, is made up of

4.1. A traction machine.

Commercial mechanical traction equipment is used. It is very common to use agricultural tractors, although the larger cleaners are mounted on lorries to give them greater stability and load capacity.

In solar farm installations where there is little space between the panel structures, small tracked tractor vehicles are used, which are very stable due to their lower centre of gravity and high manoeuvrability, and which have been specifically designed for this work.

4.2. A base with its hydraulic articulated arm.

All these solar cleaning equipment have an articulated hydraulic arm, which has a base that is coupled to the main machinery and serves to bring the cleaning equipment closer to and position it on the solar panels.

This hydraulic arm has various degrees of freedom, depending on the size of the equipment and the desired performance, being more or less complicated, depending on the manufacturer of the solar panel cleaning equipment.

It is very common to use the same telescopic arms as for road maintenance ditch clearing equipment.

They can be very complex equipment, with their own hydraulic system powered by the tractor’s cardan shaft.

4.3. The solar panel cleaner itself.

This is a system independent of the previous one, with a geometry that adapts to the shape of the solar panels, being completely flat for the classic photovoltaic panels, and concave for the concave reflector panels.

This is placed at the end of the previous articulated arm, and can be placed in the central part or it can be moved with a rack and pinion to move off-centre with respect to the articulated arm and widen the cleaning position.

This equipment also has at least one more degree of freedom by incorporating a cylinder that provides a rotation or angular displacement with respect to the articulated arm, as it must be able to clean both solar panels on the roof and on the sides of the sheds, as well as those that are angled in the solar farms.

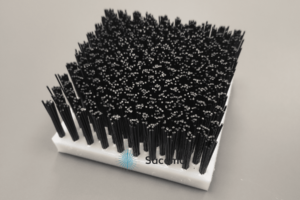

In this cleaner are placed the different types of industrial solar panel cleaning brushes that can be used, depending on the working conditions of the solar renewable energy generation installation.

There are cleaning systems with cylindrical brushes, with side sweeper brushes and even with strip brushes, and not all brush manufacturers agree on the type of filament to be used, as there are nylon brushes that absorb some water, polyethylene and polypropylene brushes, although they all end up cleaning, it is not the same to clean in one way or another, and in one place or another.

4.4. Digital positioning system with respect to the solar panels

One of the most notable features, which adds the most value to the solar garden cleaning system, is that many manufacturers have developed a digital system to control the position of the cleaner with respect to the solar panels, so that the system has a series of sensors that bring the cleaner closer to the panels and maintain the position with respect to the panel.

They are able to have sufficient speed of response to separate the cleaning equipment from the panels if an unexpected movement or destabilisation occurs, such as when the driving machine hits a pothole, and act on both the articulated arm and the end cleaner.

Depending on the degree of technological development of the equipment, the system is able to recognise the panel and do the automated cleaning, or in the simplest equipment, an operator brings the equipment close to the panel by hand, and it is the control system that positions the brush with respect to the panels and maintains the position while it is working.

This is a very important system, as it is very common for the machines to impact against the panels and cause cost overruns.

In the simplest equipment, the technological system is carried out with position sensors that are a mere warning, just like the parking assistance system in vehicles, which beeps, but does not prevent impact.

Similarly, it is very common to install a camera system so that the operator can conveniently view all the blind spots from the control of the machine.

4.5. Water system

The cleaning of solar panels should be done wet to increase the cleaning performance and to reduce the risk of scratching and eroding the panels themselves by dragging the dust and sand deposited on the surface of the panels with the filaments.

Work has been ongoing on dry panel cleaning for countries where water is a scarce commodity, but this technology is still under development but will be successful in the near future.

Therefore, solar panel cleaning equipment incorporates a water spray system, which has a main tank that goes on top of the main machine (and a good design uses it as a counterweight to the cleaner), a pressurised water pump and a system that sprays the osmotised water in front of the brushes so that it can be used to clean the panels.

These clean the solar panels properly and do not cause scratches or minor damage.

4.6. Towing and counterweights

Depending on the manufacturer of the equipment for cleaning the photovoltaic solar panels, the size of the equipment and especially the weight of the equipment and the distance between the equipment and the tractor, it is necessary to mount the whole system on a trailer or implement and provide it with counterweights, as it is equipment that can cause stability problems and risk tipping over if the solar cleaner, with a considerable weight, is carried far away from the centre of gravity of the machine.

5. Cleaning by means of autonomous robots.

This is the most technological cleaner, in which autonomous robots are placed at the ends of the solar panels and carry out an automatic cleaning cycle, with minimum human intervention.

It is a challenge and a marvel of engineering, as they have several challenges to meet:

- Energy, as it is not the same to be powered by a battery (or several), with the consequent problems of thermal differential in desert areas, as it is to have the equipment moving with a cable that has to be rolled up and unrolled from one of the sides, which can be very complicated in the case of long distances.

- The water cleaning system is even more complicated, as it would increase the weight and there would be a risk of collapse of the structure or of the solar panels themselves, which means that they have to have a water tank near the panels and that these are fed with a roll-up hose.

- Guidance, which can be mechanical, in which the cleaner is a walker that advances over the panels with wheels or tracks, or an autonomous system that is smaller and capable of walking in any direction, mapping the surface of the solar panels, as is the case with garden mowing robots or domestic hoover robots.

The big disadvantage of such equipment is the high cost and the need to install one piece of equipment for each cleaning row, or to opt for one of the small robots that can be moved from one row to another, raising doubts as to its cost-effectiveness.

Technology is advancing so fast that we will see robots that do the complete cleaning of the solar park by themselves, without human intervention, and therefore, they will work 24 hours a day, 7 days a week, obtaining the best possible performance for the solar park that owns these autonomous solar cleaning equipment.

If you want to know more about the cleaning of solar farms and our specially designed brush for these solar farms, do not hesitate to contact us.