Solar Panel Cleaner

The Sacema solar panel cleaner is a solar cleaner designed for large solar farms with agricultural tractors.

The Sacema solar cleaner is specifically designed to be used with agricultural tractors, making it a competitive option for large photovoltaic plants where an agricultural tractor can access, as well as for smaller installations where the panel inclination or lack of continuity prevents cleaning with remotely controlled robots.

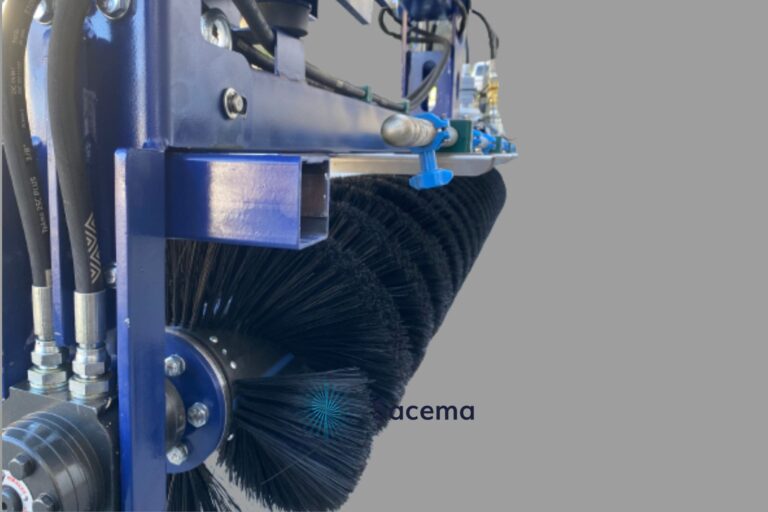

The solar panel cleaner is a system composed of several machines, starting from the agricultural tractor itself, with the arm or hydraulic crane attached, which with its 5 movements (3 cylinders and 2 rotating crowns) positions the brush at any angle on the panels, generally attached to the tractor’s front 3-point linkage.

The brush itself includes its frame, technical brushes, irrigation water spray bars, and distance measurement sensors for working distance to the panel.

A rear water tank incorporates a pressure valve that propels the water through the arm to the brush sprayers.

A video camera system, installed in quartets: 2 on the arm, one above the tractor cabin, and another on the water tank.

An instrumentation and control system for the movements of the arm and brush using a joystick, as well as a PLC and HMI to control and inform the working distance of the brush against the panels.

If you have any questions about this or any other brush, please do not hesitate to contact us.

- Hydraulic Arm

It consists of 4 blocks: the base where it attaches to the tractor, 2 sections with pivot points, and the brush coupling. It is made of a steel structure, providing sufficient strength and degrees of freedom to position the brush where needed and in the required working position.

It is a fully symmetrical solar cleaner, allowing its orientation with two rotating crowns. The first is positioned between the base and the first section of the arm, allowing the whole unit to orient from -90º to +90º from the base. The second, positioned at the beginning of the second section, also allows an additional -90º to +90º rotation.

Thus, the user can make the brush clean the panels both to the left and to the right of the tractor’s forward direction, being completely symmetrical. This is very useful for solar farms with long corridors, as the tractor does not need to return empty at each corridor change, if it only had the option of cleaning to the right as most cleaners on the market.

The solar cleaner arm also has 3 hydraulic cylinders, in addition to the two rotating crowns: The 1st and 2nd to lift/lower and extend/retract, moving the 2 sections of the arm, and the third allows the final wrist orientation of the brush.

The cylinders have hydraulic brakes to prevent the user from constantly correcting the working position due to pressure loss in the hydraulic groups.

Additionally, an extra support bar under the three-point hitch, with idle support wheels, is available to reduce the pitching of the equipment when working at extended positions, in case of large brush dimensions.

Furthermore, it is on the solar cleaner arm, not the brush, where the cleaning aid video cameras are placed.

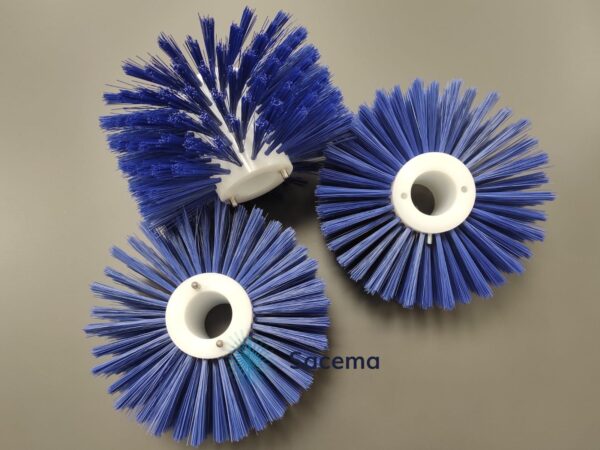

- Brush

The other fundamental component of the solar panel cleaner is the brush block.

This block consists of its own frame that attaches to the arm for easy transport, a rotating axis by hydraulic motor, the brushes themselves, water spray bars, and sensors.

The brush mounts 2 stainless steel bars for irrigation, positioned parallel to the brush (one on each side), incorporating a series of water sprayers and their respective solenoid valves that open or close according to the operator’s needs from the tractor cabin.

Additionally, 4 sensors (2 on each side) can be installed to measure the distance (adjustable) from the panel to the sensor, facilitating the operator’s work with the brush if they do not have a clear view.

- Water Tank

The solar panel cleaner has a rear-mounted water tank on the tractor that serves as the storage for irrigation water.

Usually, it has a capacity of 1500 liters and is suspended from the tractor’s rear three-point linkage bars, but other capacities and systems that are not suspended but towed can be chosen.

A visualization camera is incorporated at the rear of the tank, as the operator does not have a view of the back of the tractor when reversing.

- Tractor

It is the tractor machine and carrier of the equipment, providing movement and supporting the cleaner and its hydraulic power.

It is the buyer’s responsibility to select the tractor if not interested in acquiring the complete tractor+solar cleaner set, ensuring it has sufficient strength and stability to safely perform the cleaning tasks.

In such cases, we recommend conducting a stability study of the tractor and solar cleaner set.

- Video Camera System

The equipment can incorporate a video camera system, aiding and facilitating the cleaning operation, and is recommended for safety to give the operator a view of the blind spot behind the water tank.

One camera on the top of the cabin, two cameras on the last section of the arm, and a fourth on the water tank to assist in reversing, complemented by a display screen for the images mounted in the cabin.

The operator can modify the viewed image with buttons on the screen itself, and it is important to clean the lens of the cameras on the arm frequently.

- Sensor System

The equipment can incorporate a sensor system on the brush, aiding and facilitating the cleaning operation, and is recommended for safety to provide the operator with information on the brush distance to the panels to avoid impact and collision.

The distance is configurable by the user, and all information is displayed on the SIMANTEC HMI PLC screen incorporated in the tractor cabin.

It is an informative system, similar to the parking assist system in vehicles.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

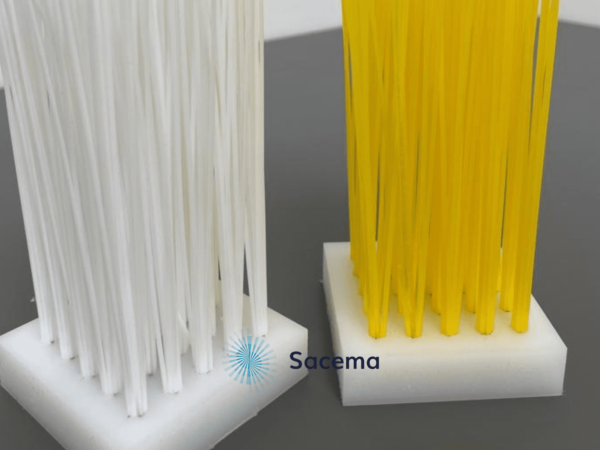

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS