Cylindrical Brush

The cylindrical brush is custom-made according to the customer’s specifications. Its cylindrical shape facilitates uniform contact with the surface.

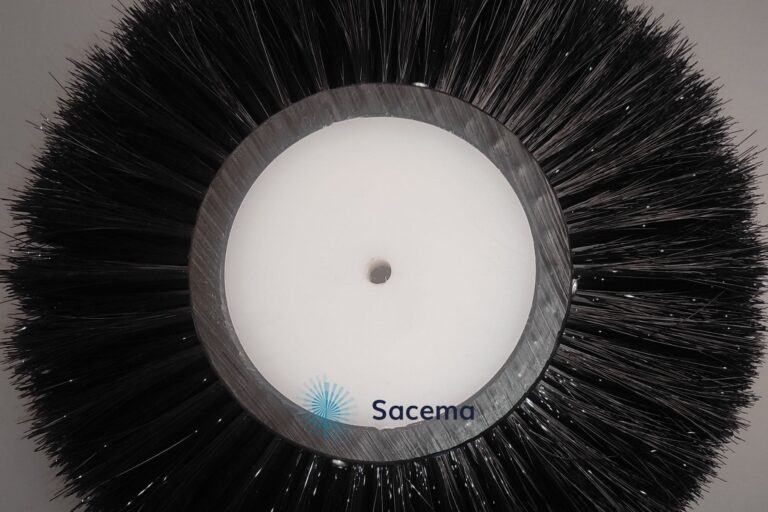

The cylindrical brush is manufactured from a cylindrical body, usually solid circular or tubular bars. Due to its cylindrical shape, they are designed to be mounted on shafts (or shaft ends) that rotate to perform dynamic brushing tasks.

Its cylindrical design allows uniform contact with the surface, providing efficiency and effectiveness in various industries and applications in combination with a unit that powers the rotation and transmission of power.

It is used for tasks such as cleaning, deburring, aiding in the movement of parts, polishing, and dust removal, among others, and always in dynamic applications.

As with other types of industrial brushes, cylindrical brushes are custom-made according to the customer’s specifications and needs, especially when it is necessary to work on the cylinder body to fit the shaft requirements and particularly the brush’s attachment to the shaft.

Cylindrical brushes are integrated like other solutions:

- Belt cleaner, whether the standard model or the heavy-duty for heavy industry, forming a motorized unit with a cylindrical brush.

- Roller conveyor, placing a large number of cylindrical brushes working in parallel.

- Solar panel cleaner, consisting of a hydraulic crane for tractors that includes these cylindrical brushes.

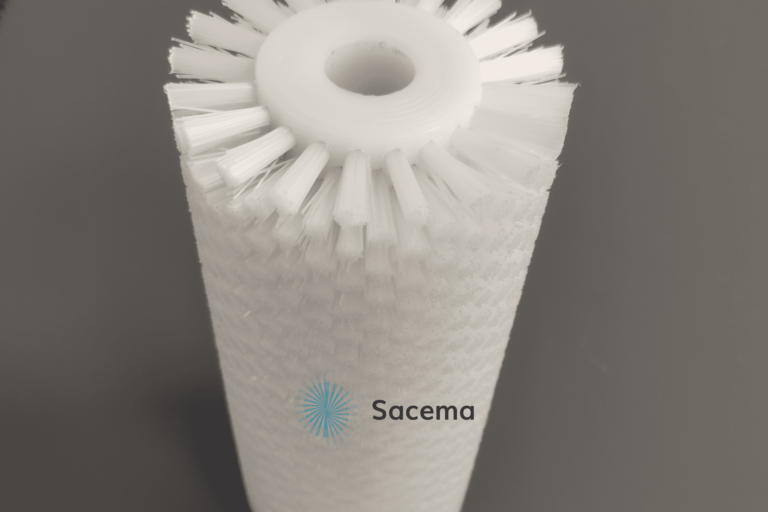

Cylindrical brushes can be manufactured so that the filaments protrude at an angle from the body, especially when aiming for the working surface to be slightly larger than the body length.

There are three main categories of cylindrical brushes according to the shape of the bodies:

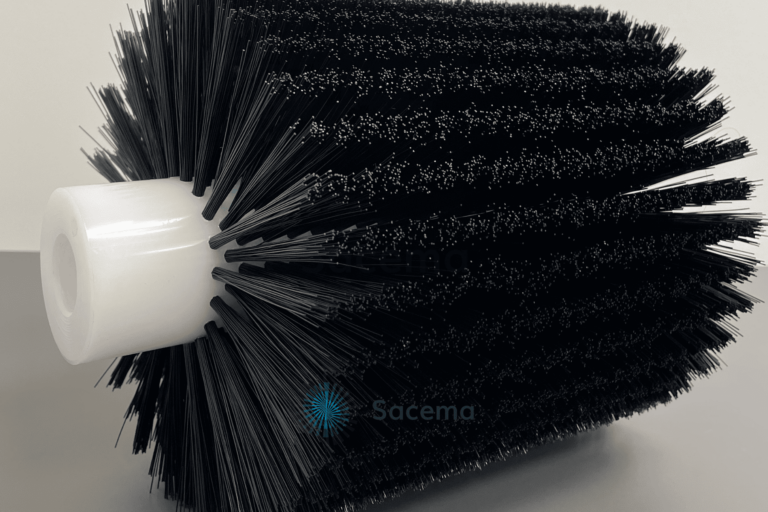

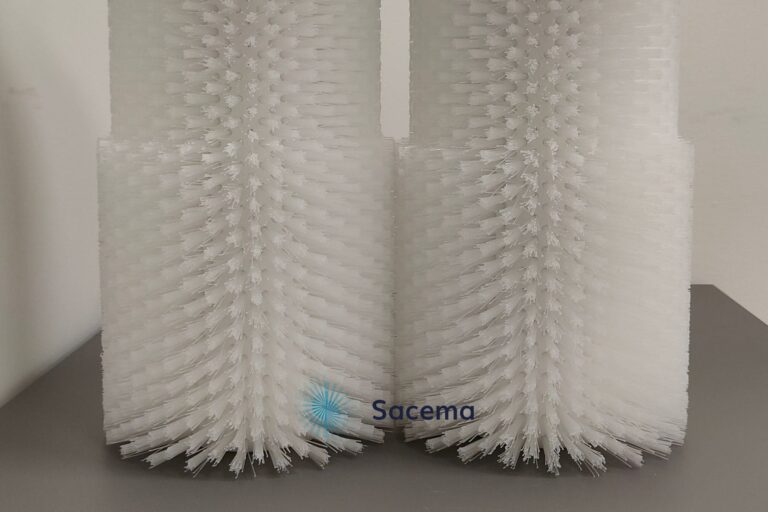

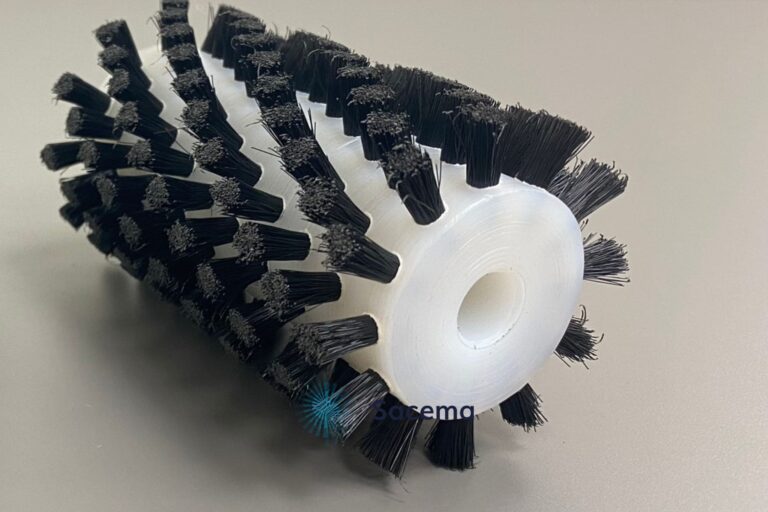

- Cylindrical brushes from a pipe: These are custom-made industrial cylindrical brushes starting from a pipe to the desired length. The pipe is usually a pre-drilled plastic bar, onto which bushings are placed at the ends to reduce and support the shaft on which the cylindrical brush rests.

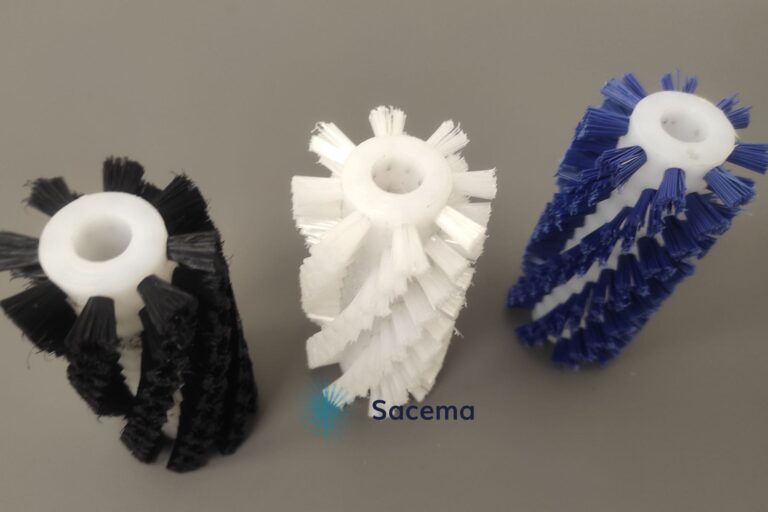

- Cylindrical brushes from a solid bar: These are custom-made industrial cylindrical brushes starting from a solid bar to the desired length, which is drilled in its axis to prepare the hole through which the brush is inserted and fixed to its shaft.

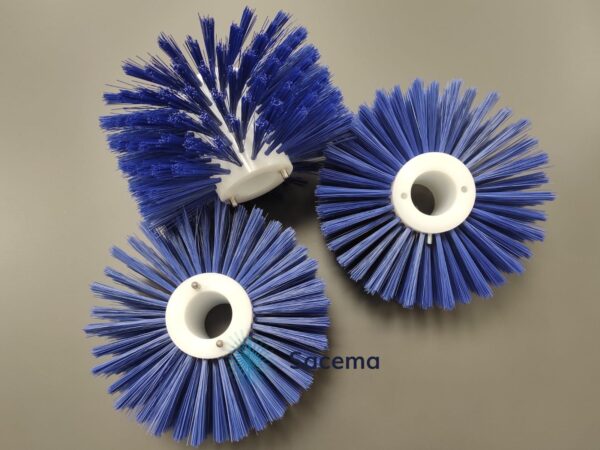

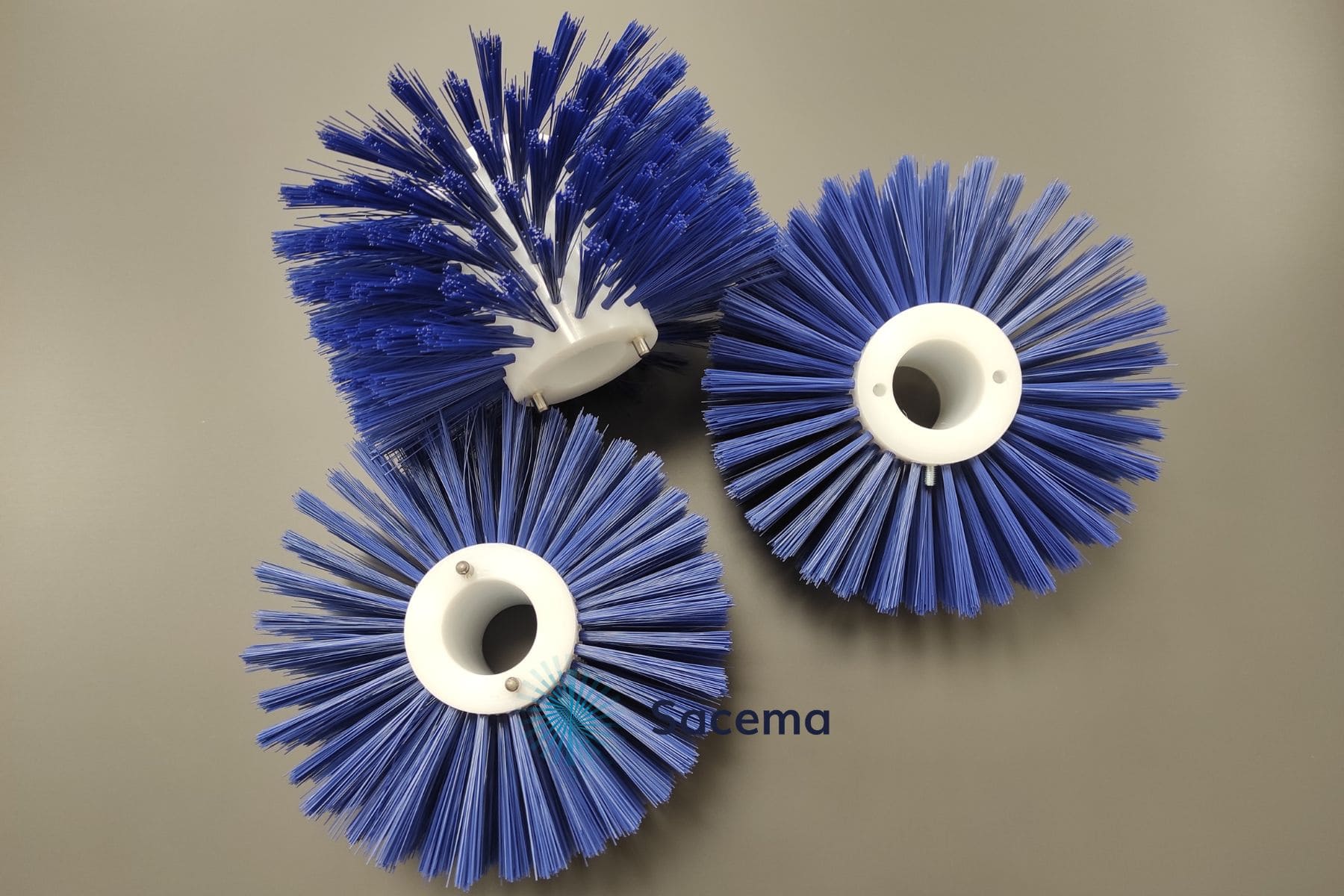

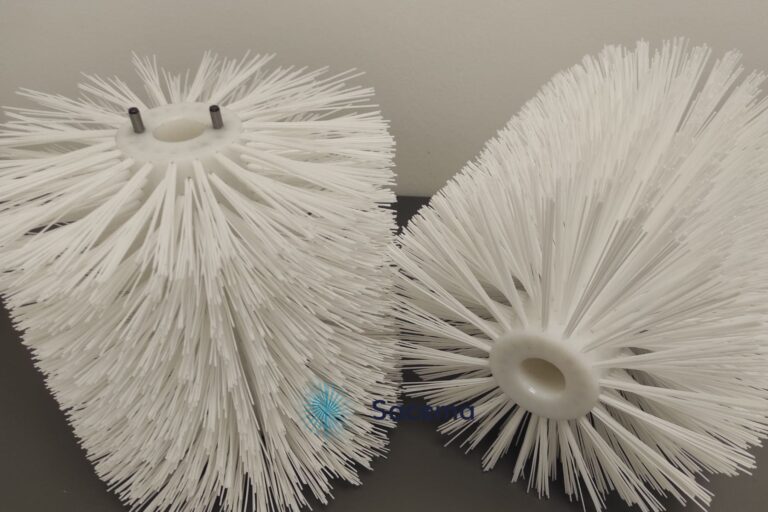

- Cylindrical brushes from a molded body: These are very specific brushes where the body is formed through an injection molding process, already having the final design and shape. They are especially used in sectors with minimal variations in sizes and high consumption, such as the rings of street sweeper brushes or the horticultural sector.

If you have any questions or queries, please do not hesitate to contact us.

Similarly, according to the shape and distribution of the filaments, we have the following types of cylindrical brushes:

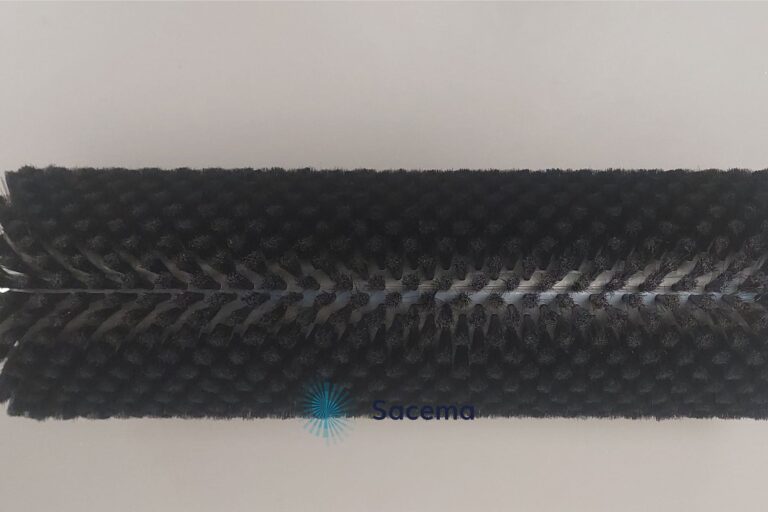

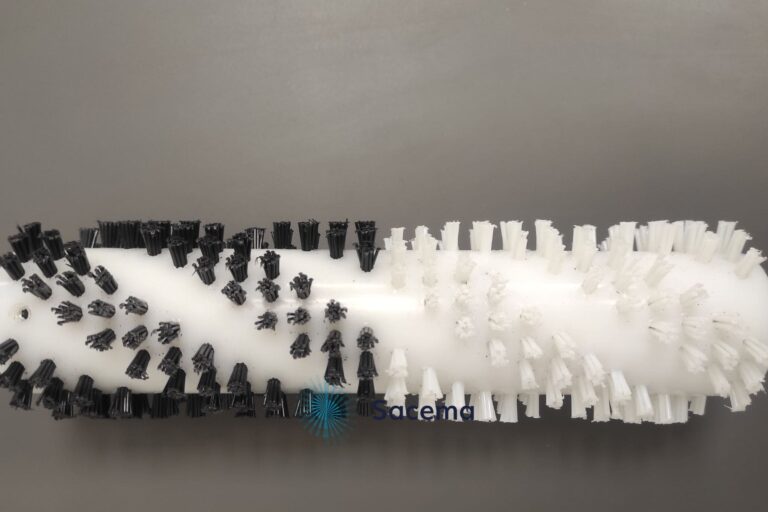

- Dense cylindrical brushes: These are the most classic, where, depending on the diameter of the brush body and the required density according to the application, the tufts of filaments are uniformly placed on the cylinder’s surface. They can be staggered or parallel depending on the application.

- Cylindrical brushes with blades or parallel/inclined rows: This is a simplification of the dense version, where gaps are intentionally left between the filaments so that the brush has filaments in the form of blades, either parallel to the shaft or with an inclination angle. The purpose of these gaps is to provide relief for the evacuation of the material to be moved, and they are typically used in the central brushes of sweepers that do not have suction to complement the brush.

- Cylindrical brushes in V-shape: This is an evolution of the parallel rows brush, but in V-shape, with the vertex generally in the plane of symmetry of the brush. The purpose of the V is to direct the residue either towards the central area of the V or towards the outside.

- Cylindrical brushes in spiral or helical form: This is the most complex form of all cylindrical brushes, where the filaments are placed in rows that follow a spiral shape along the length of the brush. This spiral can be of a single row or multiple, even in different spiral directions, and can be defined based on the pitch and the total number of turns.

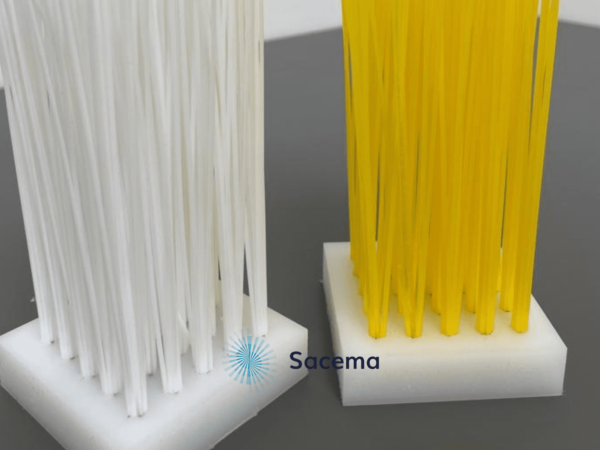

Technical cylindrical brushes, like other industrial brushes, can be specified with synthetic, natural, or wire filaments.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS