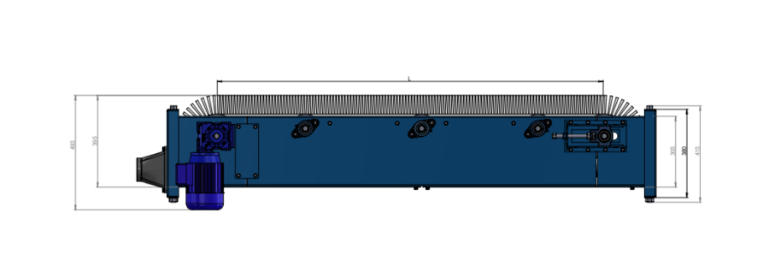

Crossbelt Cleaner

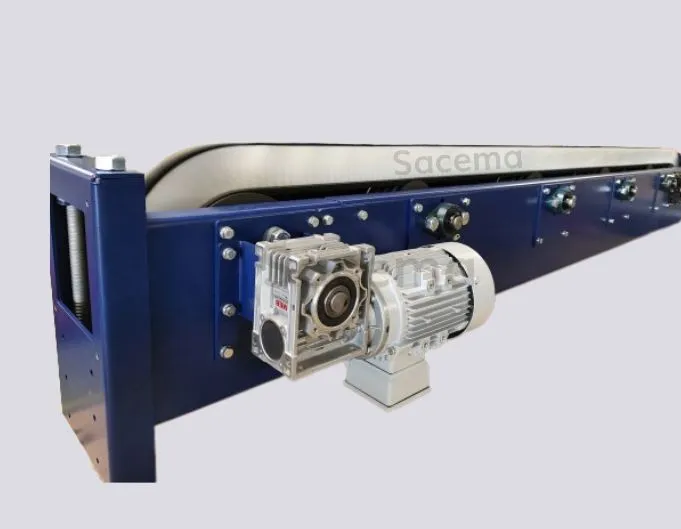

The Crossbelt Cleaner is a complete brushing unit based on a pulley system that moves a set of belt brushes to perform transverse cleaning.

The cross belt cleaner is one of Sacema’s most technical products, as it is an evolution of the traditional belt cleaner, where it is necessary to send the residue to the sides of the belt or surface.

Therefore, this cleaner can be summarized as a motorization of a set of belt brushes to complete a transverse brushing unit that is easy to integrate and install in the industrial process.

As it is a system with a belt as its core, a set of pulleys (one drive, some idle, and the last with a tensioner) is required.

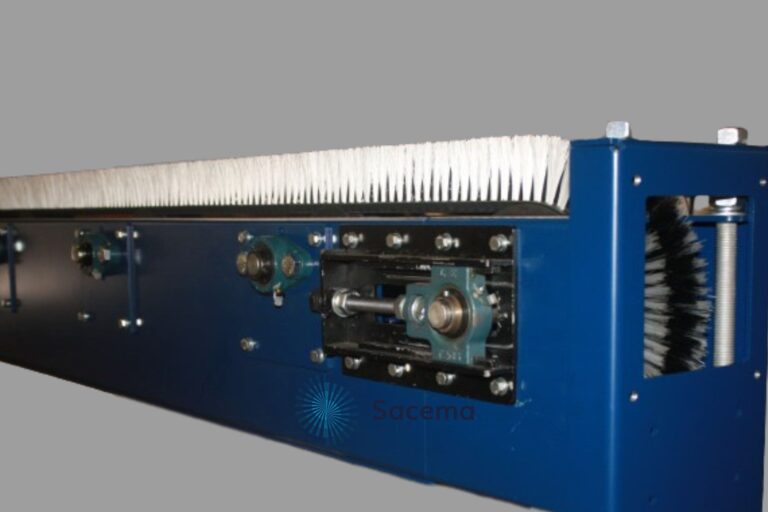

Initially, it is a product designed and conceived for cleaning large surfaces where it is not desirable to clean with a cylindrical brush that pushes the residue towards the machine or the product itself, and being a transverse working method, all the evacuation of excess material and residue is concentrated on one side of the machine.

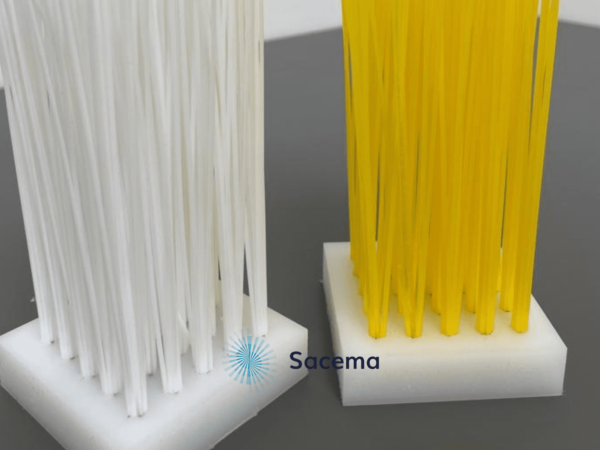

Due to the versatility of the belt brushes, by selecting the appropriate filament, the cross cleaner is also used for all kinds of applications in industrial processes, including the food industry, for all types of work where a technical belt brush is to be integrated: piece movements, surface cleaning, fluid application, etc., and always considering applications where transverse work to the process is desired.

Additionally, the food industry version is commonly manufactured, where the main components are made of stainless steel, the brush complies with food regulations, and it is up to the customer whether the gear motor remains standard, is encapsulated, or the certified versions for the food industry are chosen. Also, the belt material is food-compatible, and even metal-detectable polyurethane belts can be chosen.

At Sacema, we have the material means, technological tools, and skilled human resources to develop the turnkey project for the motorized belt cleaner, design its customization, as well as manufacture, install, and commission it with the necessary instrumentation.

If you have any questions about this or any other brush, please do not hesitate to contact us.

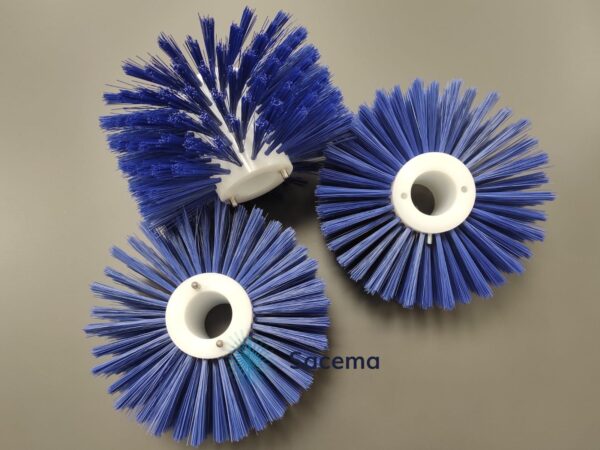

The cross belt cleaner is a motorized brushing unit of an industrial cylindrical brush composed of the following components:

- Support plates made of powder-coated carbon steel 5 mm thick.

- Solid shafts from 25 mm chrome bar, with one for each pulley.

- Cast pulleys with centering pieces and tapers.

- 4 industrial belt brushes.

- The last pulley incorporates a double tensioner.

- 25 mm UCFL bearings.

- M20 height positioning spindles.

- 1 HP gear motor that rotates at approximately 285 rpm.

- An aspiration hood can be installed at one end.

- An electrical box that incorporates a speed controller that drives the motor and adjusts the rotation speed to the desired process and adjusts according to brush wear.

Due to the needs arising from users of the belt cleaners and the diversity of applications, the following have been developed:

- Supports

Pillars are available to support the cross cleaner on the floor, designed for surfaces or machines at floor level. In this way, the cross cleaner is not modified or supported, but rather a small pillar is added on each side of the belt.

Supports are also available to fix the cross cleaner to a beam or structural element adjacent to the piece to be cleaned.

- Aspiration

It is a need that arises after the cross cleaner’s commissioning, where its installation generates dirt or dust, which is material and dirt that was adhered to the belt or surface, that the brush removes from the surface, and it is necessary to add dust aspiration.

As standard, an aspiration hood is provided to prevent dust diffusion, and aspiration hoses are connected to it for dust capture, which can be interchanged from one side or the other.

Depending on the amount of dust generated, the required aspiration flow is calculated, and the filter size and necessary vacuum power are dimensioned to avoid clogging and ensure sufficient aspiration capacity while working.

Request fast quotation

If you are interested in this product write to us and we will give you a personalized quotation.

Other products

Can't find what you are looking for?

We design and manufacture your custom-made brush

If within our catalog you do not find a suitable solution to your needs, contact us without obligation and we will offer you a customized solution.

SECTORS

APPLICATIONS