The issue of static electricity is not a minor problem in the industry. It has been the cause of serious accidents throughout history, especially in installations where they have non-conductive materials in continuous rubbing, such as large sheets of paper, fabric or plastic in the newspaper printing, chemical, textile or plastic bag manufacturing industry, among many other applications.

Static electricity

Since the origins of humanity, people have wondered why it gives us cramp to touch certain surfaces, we get our hairs stand on end, or when school children rub a pen with pieces of paper, and they stick to the pen.

This phenomenon is called static electricity and originates from the continuous friction of surfaces, whether conductive or insulating, that create excessive positive or negative static electrical charge on the surface of materials.

This electric charge can impose significant risks in industrial processes, as they can lead to uncontrolled electric shocks, putting both people and installations in great risk.

The solution

The simplest method to make static electricity disappear is to electrically join the surfaces with ground connection and this is a method to derive this excess electrical charge by wiring and grounding the conductive surfaces. In most machines, this process is simple, as the frames are grounded by a wired joint on any screw in the machine frame.

But there are numerous occasions when surfaces cannot be directly contacted by wires, and it is necessary to ground through flexible contact elements, and that´s where industrial brushes come in.

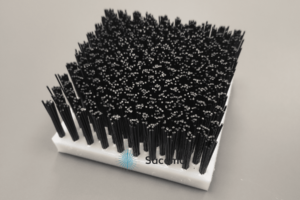

Specific industrial brushes have been developed, which are the antistatic brushes, that solve this problem of surface grounding in a simple and economical way whatever the electrical voltage.

The main feature of these brushes is that the filaments are made of electrical superconducting materials: stainless steel and carbon fibre.

Types of antistatic brushes

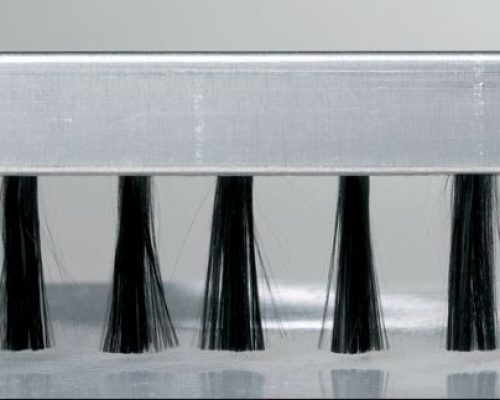

- Antistatic strips are strip brushes that replace plastic filaments with stainless steel wires or carbon fibre bristles, which are attached to aluminium supports with different shapes, which come in standard length of 1000 mm. The strips are very useful when you want greater safety and that large work surfaces are derived to ground.

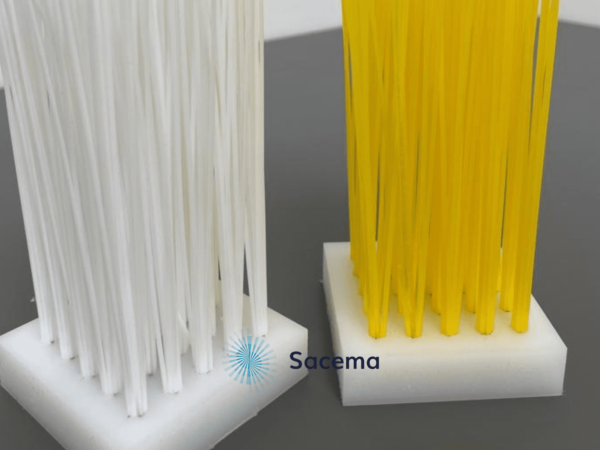

- As a complement, we have antistatic wicks, which consist of a grouping of carbon fibres pressed to an electrical terminal. They have the advantage of their simplicity and therefore, are easy to integrate into the ground wiring of the electrical connection, since its termination is an electrical connection type Faston.

In the next video, I explain to the sales team the advantages and applications of antistatic brushes.