FAQ - Frequently Asked Questions

If you still have any questions about industrial brushes, please do not hesitate to contact us.

Generally, the minimum order quantity is one unit, although this depends on the family and type of product. Customised industrial brushes and brushes for sweeping machines, both industrial and street cleaning, are made individually, because the minimum order is 1 unit.

Metal brushes for drills, grinders, pipe cleaners are supplied in boxes, generally of 12 units.

The strip brushes are supplied in strips of 3 metres, although they can be cut to length.

This is the million dollar question, as the duration of a brush depends on many factors:

The measurements, since, in general, the longer the bristles, the greater the useful length of the brush available for wear.

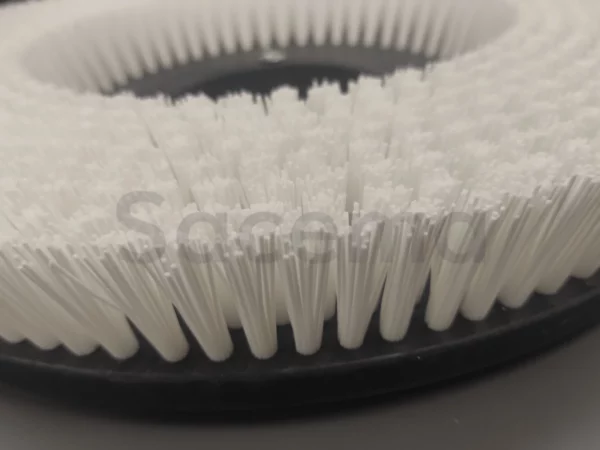

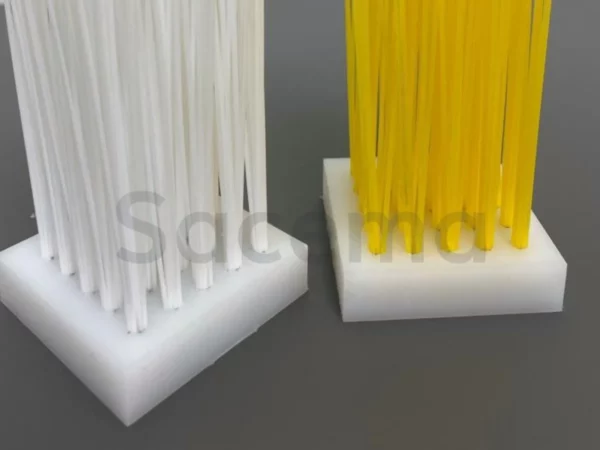

The material of the filament, since technical filaments have greater resistance to abrasion, and therefore longer duration than the most common ones.

The density of the brush, since the denser the brushes, the more working material and therefore, theoretically, the longer the life of the brush.

The working method is what has the greatest influence, as a brush that is working in poor conditions (excess pressure in general) suffers more and therefore lasts less than the same one working correctly.

Yes, we strive to avoid having problems but when there are problems, we answer for them. We have digitalised procedures to correctly manage any doubts, queries or after-sales complaints in order to provide the best solution in the shortest possible time.

Since the minimum order quantity is usually one unit, samples can be manufactured and supplied. However, to manufacture them there is a higher cost of preparation and machine configuration, which makes the samples more expensive than the serial products.

Industrial brushes are, by definition, customised products, so it is possible to configure the brushes in multiple combinations. However, there are some combinations that are not feasible to manufacture.

Do not hesitate to contact us to help you in the correct definition of the brush you need.

Yes, our day-to-day work is based on proposing the most suitable brush for the use or work required. In general, users are unaware of all the features and options that we can achieve with industrial brushes, so the sales team proposes improvements and makes suggestions of the type of industrial brush that best suits their needs.

Sacema uses top quality materials for the manufacture of the brushes and has a quality control system, which minimises problems with the guarantee of the brushes.

When there are problems, the technical team reviews the project and analyses the origin of the problem, even replacing the brush under warranty if the failure is attributable to the manufacturing process or the quality of the materials used.

The hardness of the industrial brush while working against a surface is obtained by combining different parameters that define it:

The easiest to change is the filament diameter measurement: the greater the calibre or size of the filament, the more rigid it is, and therefore the brush is harder.

Similarly, the longer the brush filament, the softer the brush. Although greater or lesser hardness can be obtained by maintaining the previous parameters constant, with the density and diameter of the tufts. The more filaments the brush has, the harder it will logically be.

The last variable that modifies the way in which the industrial brush works is the material of the filaments. Logically, the wires will be harder than the synthetic ones, and the latter harder than the natural ones, and of course from one material to another, the rigidity also changes.

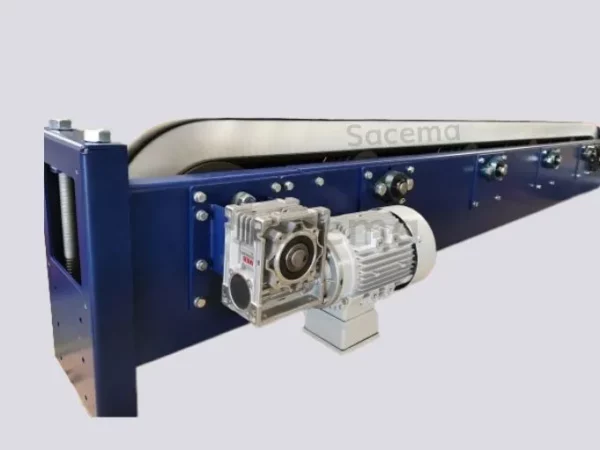

The delivery time depends very much on the product to be delivered and the quantities needed.

For street cleaning brushses, the most common sizes of side brushes and some central brushes are usually kept in stock to have a very short delivery time.

On the other hand, custom-made industrial brushes depend a lot on the quantity demanded, the type of brush, the rotation of this family of products, the avaliability of the materials that need to be used at the time, and also the workload of the factory.

Well, sometimes it does. When you plan to manufacturate similar products and have a similar machine configuration, you have lower costs and therefore we can make offers. Similarly, the larger the quantity, the better the price.

Special campaigns for certain products are usually activated and communicated through our newsletter and social media. We recommend that you follow us to be aware of and take advantage of the many special offers that we make throughout the year.

¿Quieres ponerte en contacto con nosotros?

Si tiene todavía alguna duda sobre cepillos industriales, consúltenos sin compromiso.

Blog

The Value of Solar Gardens: Maximising their Energy Potential

In the ongoing search for sustainable and renewable energy sources, solar farms

A Challenge for Technical Brushes

In the industry, the demand for technical brushes that can withstand extreme

Historical Tour of Brush Manufacturing

The Brush manufacturing has been a key activity in industrial history, and